Pre-filled syringes are an increasing segment of the market for drug packaging. The market value of pre-filled syringes is expected to rise from $4.9 billion in 2018 to above $9.7 billion by 2025¹. The failure of pharmaceutical packaging has a detrimental effect on the patients’ health conditions and loss caused by product recall. One of the failure modes of a syringe is the damage to its components such as plunger due to excessive stress built up from the mechanical loading. As a result of a failure, the syringe will lose its sterility². Therefore, it is very critical to consider the strength of a material under different loading conditions when designing a syringe. In addition to the mechanical strength of the spring components, the fluid properties of the medication should also be considered. It is important to consider both the structural and fluid behavior to design an optimal syringe. For example, a high viscosity fluid would require a higher injection force, which as a result would make the patient uncomfortable. Thus, understanding the requirements of pressure and force is of utmost importance for the design of a syringe. The optimum design of a syringe that has greater strength depends on the needle gauge and length, time, fluid volume to be dispensed, and barrel inner diameter³.

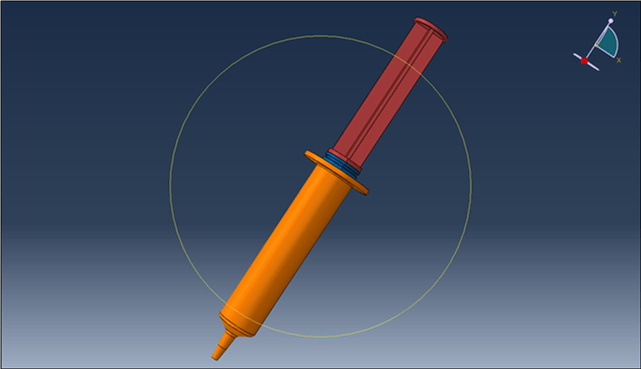

Using Abaqus/CAE finite element analysis (FEA) software, we can model and analyze the behavior of the syringe at different applied pressures. The syringe analysis is a highly nonlinear problem due to contact, large deformation and material flow, and therefore requires robust solution algorithms to analyze a syringe. The contact nonlinearity arises due to contact between syringe piston and cylinder, between piston and fluid, and between fluid and cylinder walls. The material nonlinearity and large deformation arises due to material flow behavior. We can analyze and understand the strength of the syringe along with the behavior of the fluid being injected. The fluid-structure interaction can be modeled using Coupled Eulerian-Lagrangian (CEL) or Smooth Particle Hydrodynamics (SPH) methods available in Abaqus Explicit. The analysis can be used to design and optimize the syringe so that the risk of failure is minimized. This example demonstrates one of the many capabilities of Abaqus.

As a Vias3D consultancy group, we offer comprehensive solutions for a variety of industries. The engineering and simulation team combines decades of analytical and design experience. They have successfully designed various products from many industries for strength, stability, rigidity and fatigue endurance. Our design and analyses capabilities are accomplished through advanced engineering modeling techniques such as Finite Element Analysis (FEA) using Abaqus/CAE, Computational Fluid Dynamics (CFD) and other tools. Using these advanced tools, we are able to capture complex design features and nonlinearities arising from materials, geometry and surface interactions, to simulate designs and predict their response before they are brought in production.

I will be happy to discuss your needs. Please drop me a message at [email protected] or connect with me at https://www.linkedin.com/in/santosh-paudyal-757203aa/

Contributor: Santosh Paudyal, MS, Engineering Intern at Vias3D Mr. Santosh Paudyal is a mechanical engineer with more than 3 years of professional experience. He has valuable experience in supporting clients, designing and implementing climate control systems, project management, and structure simulation using Simulia Abaqus. He holds Masters degree in mechanical engineering from University of North Dakota.

Sources:

2)http://www.ssanalysis.co.uk/hubfs/KB_Technical_Briefs/Syringe_Seal_Failure.pdf

3)https://www.mddionline.com/designing-drug-delivery-device-read-first