COVID-19’s effect on the world has been drastic as well as sudden, and in a time like this, it is imperative that all equipment be used as effectively as possible. This equipment may range from personal protective equipment to machinery used in hospitals or even factories. This mass quarantine has had numerous effects on the world as we know it. It has shut down factories, slowed down exports, and skyrocketed the number of people filing for unemployment. According to NPR’s Emily Feng, China has about 300 million migrant workers that run its factories and work in countless industries, and these workers are currently stuck inside their homes. [1]

The global economy has slowed down, effectively making various products and equipment more valuable as well as scarcer. The Institute for Supply Management released its April 2020 Report On Business. This report analyzes the economic activity in the manufacturing sector. According to the report, there has been a 30% decrease for April due to the COVID-19 impact on both customers and suppliers (regarding electronic and technical products). [2] This is exactly why equipment and machines manufactured right now must be designed not only to work efficiently but also to last. This can be achieved by utilizing modeling software such as ABAQUS or SolidWORKS.

Figure 1: Y-Shaped Airflow Splitter Model (Left), Green Oxygen Particles Simulated through Splitter (right)

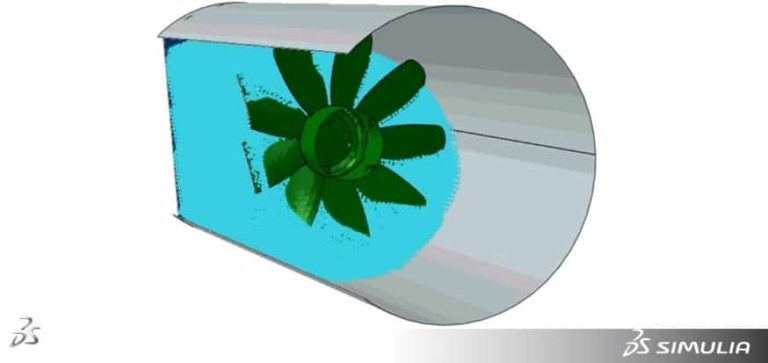

ABAQUS has a modeling method named SPH (Smoothed particle hydrodynamics). This method does not rely on a mesh as it normally would, instead it only needs a collection of points to represent a given body. These points are called particles and can simulate situations involving heavy deformation (gas flow, fluid sloshing, etc.). This is beneficial because it can give us a more accurate representation of the impact a fluid will have on the environment around it. For example, the flow of oxygen can be simulated as it flows out of a ventilator into an airflow splitter. Or singular parts of more complex machinery can be modeled to understand how they will behave, such as a cooling fan within a CPU, or a pipe with fluid flowing through it. Figure 1 shows the oxygen in an airflow splitter. This figure depicts a coarser collection of particles to make it easily visible. Figure 2 has more refined particles which will give a more accurate result.

Figure 2: Fan Simulated using SPH Method, fluid particles shown in blue [3]

These models and analysis are all conducted within specialized software. Vias3D utilizes world-leading software such as SIMULIA brand Abaqus and CATIA, that can model and simulate the behavior of complex items as well as execute an SPH analysis. Vias3D also has an excellent team of experts in modeling/simulation software with years of valuable industry experience.

The versatile modeling and simulation tools used by Vias3D can be used to conceptualize, model and simulate the fluid dynamics that occur within a variety of applications, such as splitting the airflow from a ventilator or even simulating the sloshing of a fluid in a container. Once satisfactory results have been obtained, the geometry of the parts can be 3D printed or manufactured to be used in their real-world environments.

We will be happy to discuss your needs. Please drop me a message at [email protected] | connect with me at https://www.linkedin.com/in/andres-seijas-420956175

Contributors:

- Andres Seijas, Undergraduate at Texas A&M University, Simulation Intern at Vias3D

- Santosh Paudyal, MS, Mechanical Engineering, University of North Dakota

Mr. Andres Seijas is pursuing his bachelor’s in science degree at Texas A&M University. His major is mechanical engineering and he is currently a senior. He has gained valuable experience working through internships and has knowledge on dealing with clients as well as modeling and simulating parts in FEA software such as ABAQUS.

Mr. Santosh Paudyal is a mechanical engineer with more than 3 years of professional experience. He has valuable experience in supporting clients, designing and implementing climate control systems, project management, and structure simulation using SIMULIA Abaqus. He holds a Masters degree in mechanical engineering from the University of North Dakota.

References:

https://www.instituteforsupplymanagement.org/ismreport/mfgrob.cfm?SSO=1 [2]

https://www.youtube.com/watch?v=RoyJcutYyJI [3]