Design of antennas is the crucial aspect of all communication and navigation on a vehicle. A typical car today has between 10 and 30 antennas to support many different standards and applications, including analogue and digital radio reception, cellular and even satellite communication, passive entry passive start systems, monitoring systems, and radars with various functions. Antennas must fulfil the specifications for radiating performance in terms of operating frequency and radiation pattern characteristics.[1]

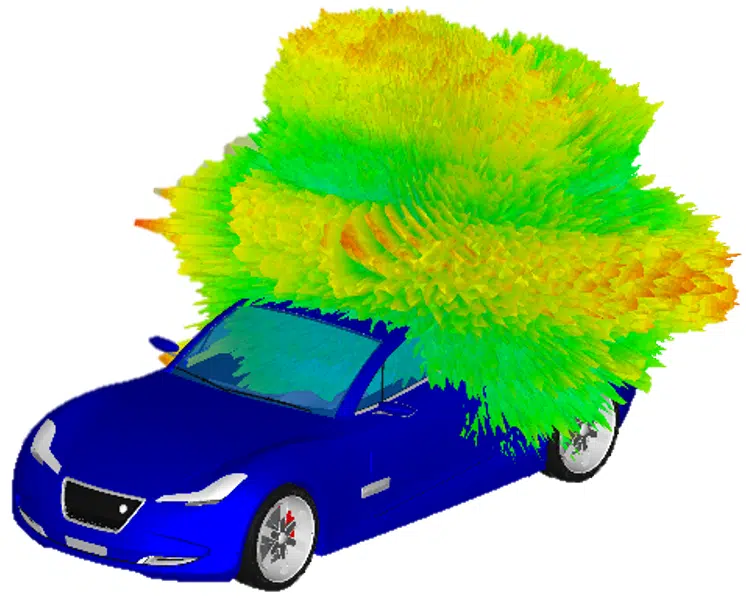

In the automotive industry, there are also strict guidelines regarding the physical characteristics of antennas mounted on a car. Simply placing an antenna on an electric vehicle can impact its performance, as the body of the car blocks, reflects, and conducts the fields radiated by the antenna. Studying this effect with experiments can be an expensive and time-consuming process requiring a large test facilities. Using the EMAG simulations can dramatically speed up the measurement process by allowing antennas to be simulated as shown on Figure 1. CST Studio Suite can reduce experiment costs and allow engineers to optimize antenna placement on a vehicle by improving its performance.

Vehicle-to-vehicle and vehicle-to-everything systems require even more detailed measurements of the vehicle in its surroundings. CST Studio Suite makes it possible to simulate antenna performance even in extremely complex detailed models more efficiently than traditional experimental testing methods. [2]

Figure 1: Antenna radiation pattern in a car. Source: 3DS.

About VIAS3D

VIAS3D engineering and simulation team combines decades of analytical and design experience. They have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modeling techniques such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG) and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.

Please email us at [email protected] or drop a message at: https://www.linkedin.com/in/arinc16/

Contributors:

Georgiy Makedonov, M.S., is an FEA Engineer at VIAS3D has over 4 years of industrial experience in finite element analysis simulation, technical support, and consulting. His professional interest involves designing, developing, and evaluation of rigid pipeline systems, teaching, and FEA analysis using Simulia Abaqus. He holds Master of Science in Mechanical and Subsea Engineering from University of Houston.

Ismary Lavandera, M.S., EMAG Solutions Engineer at VIAS3D. Ismary has 7 years of experience working on RF and Microwave systems, modeling, and simulating different types of Electromagnetic problems. She has academic and industrial experience from MHz to THz in specific topics like Antenna, Antenna Array, Power Amplifier Design, broadband matching networks design, and Filter design. She provides technical support and engineering services to customers for Electromagnetics solutions. She received her B.S and M.S degrees in electronics and telecommunications engineering from the Technological University of Habana.

References:

[1] Rütschlin, Marc & Tallini, Davide. (2017). Simulation for Antenna Design and Placement in Vehicles. 10.1049/ic.2017.0021. [2] Dassault Systems. “CST STUDIO SUITE DATASHEET. EM Simulation for Automotive Applications” [Brochure].