Industrial equipment undergoes heavy static and dynamic load during operation. So, accurate stress analysis is important to ensure uninterrupted service life and early detection of component failure. Such predictions also help to reduce operational downtime significantly.

Role of FEA in the Current Pandemic Situation

The advancement of material failure theories and their application to finite element analysis (FEA) models alongside enhanced numerical capabilities of the hardware are making FEA analysis a reliable option for predicting service-life of engineering components. Moreover, industries often need to perform repetitive tests for complex components under different loading conditions. In those cases, FEA is preferable to performing rigorous mechanical testing. FEA especially could be “the” alternative for actual mechanical testing in the current COVID-19 pandemic situation when many industries are prioritizing on the careful allocation of their resources.

Product Lines for Fighting COVID-19

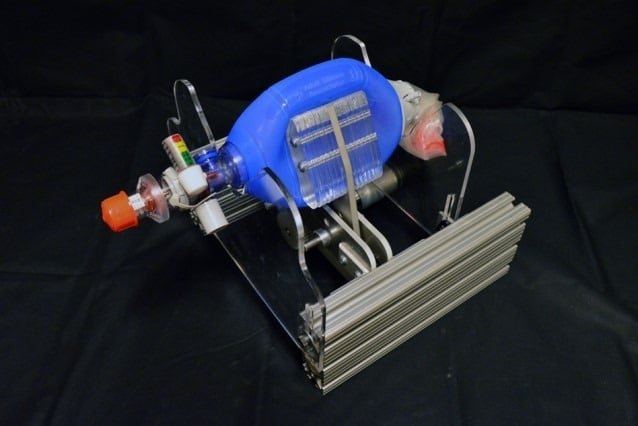

Manufacturers of industrial equipment are also adding new product lines [2] for addressing the covid-19 challenge and supporting healthcare services e.g. small-scale power generators to hospitals [3,4,5], ventilator, respirators [7] and other equipment that are aligned with the current demands.

Installing such small-scale power generators to the existing healthcare facilities could be challenging and safety for such application is of extreme importance. These generators could be delivered to remote locations (field hospitals [6]) where maintenance and troubleshooting teams might not be available in case of emergency. So, the auxiliary systems (fuel, vibration, exhaust etc.) should be designed thoroughly. A detailed FEA analysis can help to maintain a safe installation and operation of such new equipment.

We have also seen a sudden surge in ventilator production in the last few months as most of the countries had a shortage of ventilators. For example, there was a potential demand of over 100,000 ventilators in the US which was far from the national reserve [1]. Such a surge in demand often needs a quick and reliable performance analysis of the products keeping mass production in consideration. In-depth FEA can be used to improve the design concepts of these types of products in a shorter time.

Who we are:

With a dedicated team of Doctorates and master’s having strong expertise in Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG), data analytics and domain knowledge of various engineering streams, Vias3D has been providing simulation-based engineering solutions for a variety of industries including energy, health, process, utilities, and oil & gas for many years. We have strong expertise in dealing with both mitigation and life extension achieved by following the procedures given for fitness-for-service (FFS) in ASME FFS-1/API-579 within an integrity or risk reliability management framework.

For more information please visit us at – www.viascorp.com and follow us on LinkedIn at Vias3D – Virtual Integrated Analytics Solutions.

I will be happy to discuss your needs. Please drop me a message at [email protected] | connect me at https://www.linkedin.com/in/ahmed-mostafa-a6828852/

Ahmed Mostafa has received his PhD in Mechanical Engineering from University of Texas at San Antonio, Texas, USA. He has near 5 years of industrial experience as a senior engineer in design application and installation department at CATERPILLAR, Bangladesh. He has expertise in computational solid mechanics, nonlinear elastic-plastic finite element analysis, large deformation, damage, and fracture of structures made of ductile materials, additively manufactured materials, and composites. He is experienced in finite element models and performing stress analysis of complex geometries using SIMULIA Abaqus and ANSYS.

References:

- Ranney, M. L., Griffeth, V., & Jha, A. K. (2020). Critical supply shortages—the need for ventilators and personal protective equipment during the Covid-19 pandemic. New England Journal of Medicine, 382(18), e41.

- https://www.cummins.com/news/2020/05/14/employee-uses-analytical-skills-help-hospital-plan-covid-19

- https://www.caterpillar.com/en/news/caterpillarNews/customer-dealer-product/power-when-we-need-it-most.html

- https://www.cummins.com/news/2020/01/07/medical-center-turns-cummins-reliable-emergency-and-supplemental-power

- https://www.cummins.com/news/2019/05/23/experiencing-connected-hospital

- https://www.bloomenergy.com/blog/powering-field-hospitals-save-lives-during-covid-19-outbreak

- https://www.cummins.com/news/releases/2020/04/14/cummins-and-3m-partner-respond-covid-19-pandemic

- http://news.mit.edu/2020/ventilator-covid-deployment-open-source-low-cost-0326