Recently, there has been a rising awareness among the consumers about benefits of Electric Vehicles (EV) namely less dependence on fossil fuels, fewer greenhouse gas emissions, overall greener & most importantly – economical travel. Due to this, the automotive industry has experienced a push towards the electrification of 2,3,4 wheeled passenger vehicles. As the customer demand increases, all the players in the auto manufacturing field such as Tesla, NIO, Lucid Motors, Ford Motors & their supply chains have started adapting the technology of EV development. One of the automotive industry’s greatest hopes for the future is the electric vehicle.

However, designing an electric vehicle is a complex process that differs from designing a traditional vehicle. The EVs have a complicated system whose parts need to work together effectively and efficiently. Getting higher efficiency of design & charging of the EVs in less time are some of the main challenges the OEMs are facing. A typical car today has between 10 and 30 antennas to support many different standards and applications & must fulfil the specifications for radiating performance in terms of operating frequency & radiation pattern characteristics. Studying this in depth with experiments can be an expensive and time-consuming process requiring a large test facility.

Electrifying transportation isn’t as simple as just flipping a switch. This has resulted in a new set of complex challenges the OEMs need to address. Given the exponential increase in demand in EVs, consumer expectations, regulatory bodies, international laws, environment concerns are constantly pushing OEMs and suppliers to innovate new products, designs, systems at much faster pace in the evolving EV segment. This has reduced the time of a design concept, visualization, manufacturing, and supply chain significantly to less than two years.

To bring out the best EV on the streets, the OEMs must first address their challenges.

- Look into developing a connected vehicle (antenna, radar, sensors), developing a powertrain & improving design of induction motor.

- Avoid over-designing as it leads to excess material, weight and cost and system engineering helps to precise and balance targets like maximum torque, power and speed, in the context of the whole vehicle.

- Fulfil electromagnetic emission standards and human safety requirements.

- Fulfil ambitious CO2 emission targets.

- Reduction in time & cost of manufacturing the EV.

- Satisfying consumer needs & expectations.

All of this can be overcome by adapting new tools & solutions.

Developing an ideal design for EV can be tough as it must fulfil requirements for performance, efficiency, thermal, noise and vibration, etc. along with reducing the required time of the development cycle. Vias3D offers end to end solution for EV – development of antenna, radar, sensors, powertrain & more to create such a design!

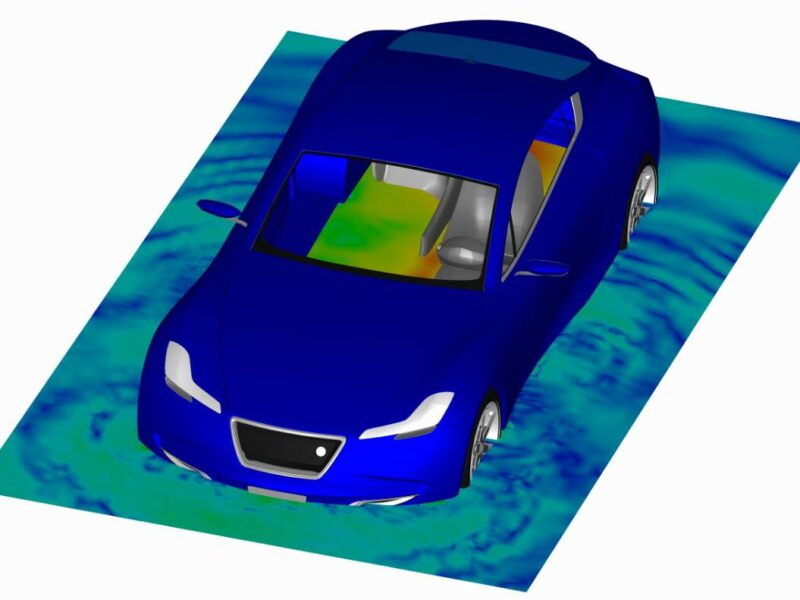

Vias3D offers CST Studio Suite®, which is a high-performance electromagnetic analysis (EMI-EMC and SI-PI) software package for designing, analyzing, and optimizing electromagnetic components and systems especially in the EV development process. It can assist you with full vehicle engineering such as Aerodynamics, Thermal Dynamics and Electromagnetic’s.

CST Studio Suite can reduce experiment costs & allow engineers to optimize antenna placement on a vehicle by improving its performance. Using the EMAG simulations can dramatically speed up the measurement process by allowing antennas to be simulated.

Using this tool, engineers can develop a connected vehicle (antenna, radar, sensors), & also use it for developing a powertrain & improving design of induction motor.

This simulation tool offers you an interactive circuit design experience, which are easy to edit or test & can be saved on the cloud. Thus, it will simplify design of the gear box & electric machine, which need to be designed carefully to avoid over-designing.

Advanced driving assistance systems (ADAS) in CST 2022 helps in virtual testing & virtual test drive with AVSimulation, thus helping in reduce simulation cost & time. When a battery is evaluated along with the electric drive on a vehicle, engineers & manufacturers can get a real idea of the performance and range of the battery rather than relying on a test at a test cell. The battery performance can be tested with real load on the battery, enabling an accurate picture of how it will perform in the real world.

This tool will also help in calculating electromagnetic compatibility for such a vehicle. With the introduction of a high voltage system, & the flow of high currents feeding the drive train, novel concepts are required to ensure that the newly developed vehicles fulfil electromagnetic emission standards and human safety requirements.

All of this, in turn, can help OEMs develop an ideal design which can be customized to meet customer needs. With the best-in-class design, reduced costs & manufacturing time, the OEMs can gain the maximum market advantage!

About Vias3D

Vias3D engineering and simulation team combines decades of analytical and design experience. They have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modelling techniques such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG) and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.