Many electric vehicles use batteries that are based on the lithium-ion technology. These batteries are some of the best current technologies for vehicle operation and are the replacement in electric vehicles for the gas tanks that are present in gasoline-based vehicles. As with all technology, there are certain pros and cons to the use of Li-ion batteries and to reduce the cons is an ongoing engineering challenge that will be around for the next few years.

With Li-ion batteries there are some commonly known issues such as the release of toxic gases if damaged and potential overheating. This, along with storage capacity are the two main areas of focus with the development of new battery technology. In addition, batteries are highly complex systems, requiring advanced engineering methods at all levels: from chemistry to cell engineering, to module and pack engineering, and finally integration into full vehicles and Dassault Systemes provides battery solutions for all of these levels.

BIOVIA solutions

BIOVIA Materials Studio supports the characterization and development of existing and new battery materials, as well as provides chemistry modeling capabilities to optimize design battery materials for aging. Coupled with the broader portfolio from Dassault Systèmes, we can accelerate the design of sustainable, safe, and reliable batteries.

SIMULIA solutions

Abaqus software can help ease the design process and understand the limitations for the design. With the use of simulation software, we can perform virtual testing such battery cell crush, circuits analysis, heat transfer and others. By doing this type of simulation, we can modify the design to better survive in the environments of our choice and under common electric vehicle stress and strain to ensure these vehicles can eventually replace gasoline vehicles in the long run.

CATIA solutions

CATIA brand provides capabilities to efficiently use battery simulation for cells. In this system-level representation, the aging, thermal, and electrical behaviors of each cell are combined to accelerate the design of battery systems.

About VIAS3D

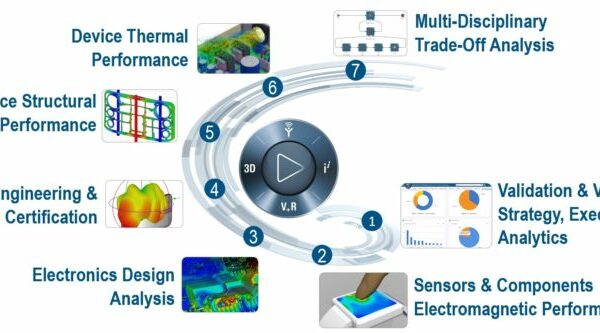

VIAS3D engineering and simulation team combines decades of analytical and design experience. They have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modelling techniques such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG) and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.

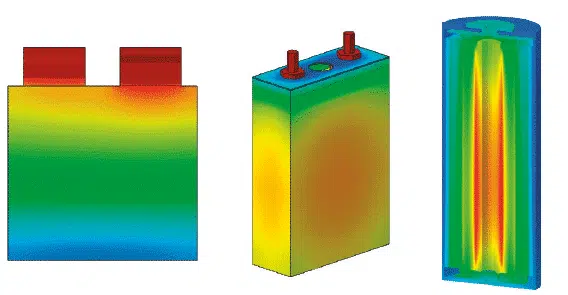

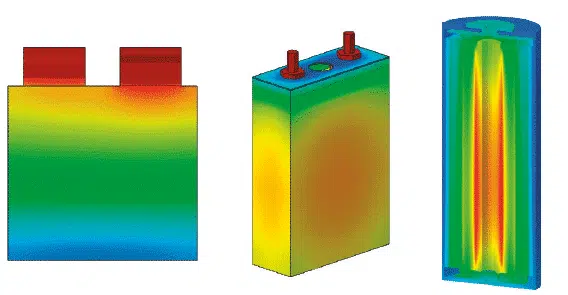

Figure 1: Electro-thermal model of cells of different geometries