Medical practices and advancements have continued to change with new studies being produced daily. In an ever-changing world, it is essential to have the ability to simulate the results of a new technology before it can be implemented within medical practice. These simulations not only are cost effective, but when done by a professional, will provide accurate results to those if they were used throughout the medical field daily.

Advancements can be made using engineering methods like finite element analysis (FEA), computational fluid dynamics (CFD), electromagnetics (EMAG) and molecular simulations (BIOVIA). Each engineering study has an impact on certain types of medical equipment that can be created with its use. The engineers also work under the guidelines set forth by the ASME and the emphasis that the FDA places on the use of simulation to gain scientific evidence, while using a physics-based model. With proper analysis, the creation of new medical machinery can be done in both a cost-effective manner along with being able to modify designs to better suit the needs that the machinery needs to accomplish.

Structural Simulation (FEA)

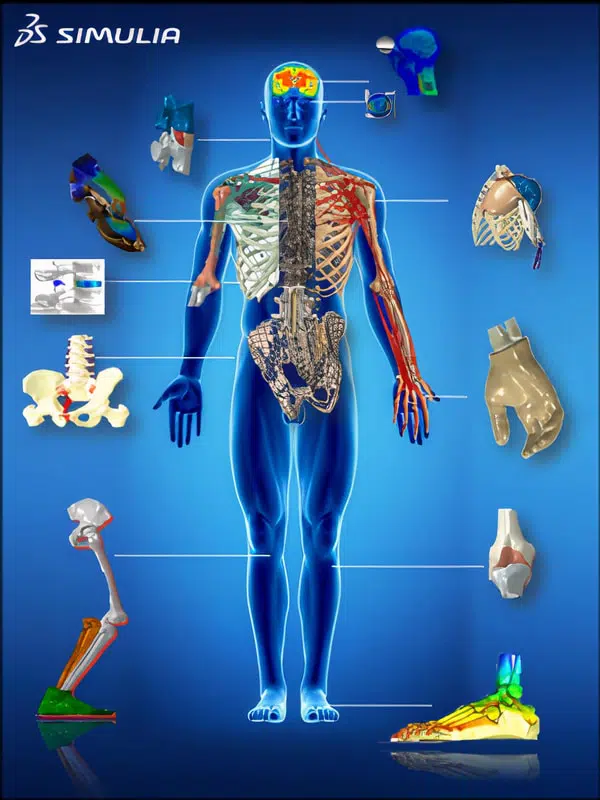

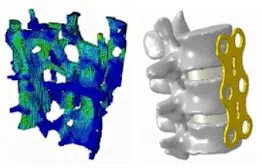

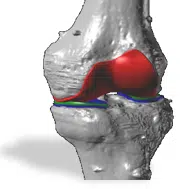

The ability to determine the response to different stimulant and stresses is the basis of this study. With the use of finite element analysis engineer experts at we can simulate various surgical cardiovascular procedures [1]. We can help the orthopedic team to model and calibrate various material properties for hip, knee, shoulder, and elbows for replacements or examine the durability of a proposed technology. With access to software like Abaqus, the team at VIAS3D is able to simulate the response of something as tiny as a syringe needle when it comes in contact with soft tissue.

Listed above are only some of the many different aspects an FEA engineer can assist with the development and testing of a medical device. While working in accordance with ASME V&V 40 standards for computational simulation of medical devices, we can help to ensure the physical credibility of the given results. These developments are what allow people to understand the amount of bone density that a patient needs in order to function through their daily lives, or what medical equipment needs to be put in place to ensure that the patient has comfort in their day-to-day walking. Our technical knowledge in orthopedics field, allows us to develop solutions associated with various motions of the bone and implant.

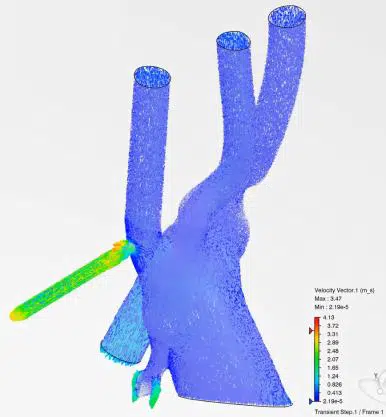

Flow and Thermal Simulation (CFD)

Studying the fluid response in the body is extremely important especially with the way our heart operates by constantly pumping blood throughout our system. From the blood flowing within our system, to the circulation of breathable air throughout our body – all of these can be simulated in systems like xFlow to allow engineers to properly analyze the response of their medical technology. For example, the creation of a new heart valve system must go through testing to analyze its flow and performance throughout varying environmental situations. The more accurate the heart-valve is to a healthy heart’s response to the same stimulant, the better the design. These parameters can be tested for within the SIMULIA suite of software and can help engineers better understand the limitations of their designs along with receiving recommendations on how to better their design to achieve the results that they would want to see. As we understand the limitations, we can also ensure that the design is also meeting the requirements set forth by ASME to ensure their flow analysis is credible. Once credibility of the design is established through simulation and the computational model is produces results similar to what is expected, engineers can move forward with standard testing and even go into clinical trials after some time.

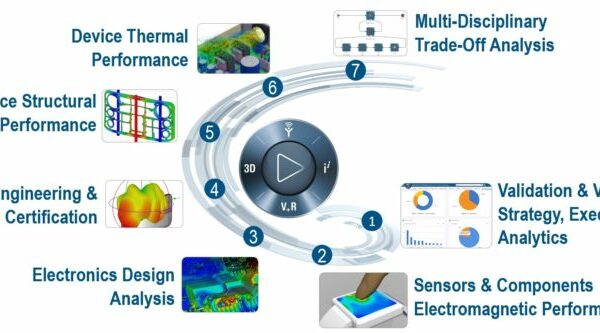

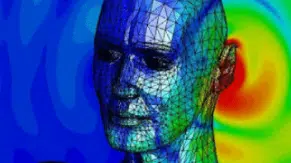

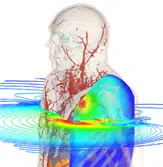

Electromagnetics (EMAG)

Electromagnetism is the study behind the creation of medical devices like the MRI machines that are used throughout medical facilities to get a better understanding of a patient’s system. These machines are far more heavy duty, so they require a bit more care when developing their models. As these machines are put through the requirements set forth by ASME, it is imperative for the engineer to ensure that along with medical imagining, EMAG can be used for a multitude of things like treatment creation, human model simulation, and smart health using body sensors and other monitoring devices [1]. With such a powerful tool under our belt, the development of medical technology can be attained quite easily. We can use our background in EMAG along with the simulations that we can run using the software CST Studio to come up with adjustable solutions to the concerns of their clients. These developments can lead to better imaging along with the ability to more accurately monitor a patient’s response to outward stimulant. Other medical devices that are potentially optimizable through EMAG include the LVAD machines and pacemakers.

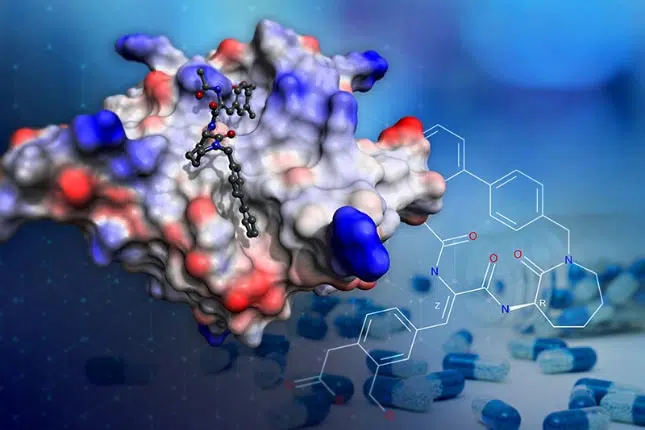

Molecular Simulation (BIOVIA)

The decline in R&D productivity is forcing companies to think outside the box to meet growing customer needs. Simply relying on physical experiments alone is not financially viable in such an environment. Researchers need to have better understanding on how and why their products work in order to better link them to project and business objectives.

BIOVIA Molecular simulations provides a fundamental atomic interaction to support product performance. In silico testing enable researchers to test concepts with minimum risk and reduce costs, which opens up new ideas to explore. By connecting the virtual and real worlds together, researchers can better guide their projects with virtual tests guiding physical ones and vice-versa. As a result, teams are able to create higher performing, safer and cheaper products, which improves customer outcomes.

Conclusion

Engineering goes hand in hand with advancements in medical practices. With the potential to change the world for the better, engineers at VIAS3D work hard to make sure that their work is not only logical, but also accurate to the needs of those in the community. The collective amount of engineering knowledge in FEA, CFD, EMAG and BIOVIA allows VIAS3D engineers to be able to work with software in Dassault Systemes to help make advances in the medical field and solve complex and challenging problems that require careful attention. As a society, we will then be able to progress and make strides in the growth of our medical services and provide patients with the care that they need.

About VIAS3D

VIAS3D engineering and simulation team combines decades of analytical and design experience. We have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modeling techniques such as Finite Element Analysis (FEA) using Abaqus, Computational Fluid Dynamics (CFD), and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.

To learn more about our technical capabilities, please visit our website https://vias3d.com/services/scientific-simulation/life-sciences/