The automotive industry needs to design and develop new car models faster than ever before because of increasing competition and customer demand. In the automotive industry, predictive technology such as Finite Element Analysis (FEA) has become the must-have tool to predict the performance of a car during the early design stage. The benefits of predictive tools include:

- Reducing product development time

- Reducing the number of design cycles

- Eliminating a large portion of physical testing necessary

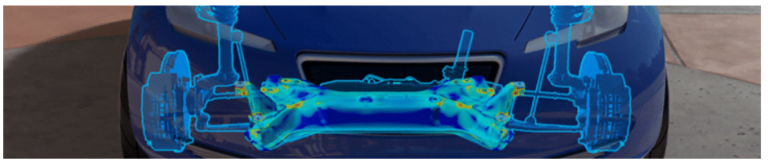

Unified FEA Abaqus workflow combines different engineering disciplines, like thermal, structural, vibration, acoustic, fluid structural interaction, and design optimization. Overall a car design should be safe, comfortable, and durable which all contribute to the performance and success of the design.

Top Applications of FEA Technology for the Automotive Industry

- Crashworthiness: Crashworthiness is the ability to protect its occupants during an impact/crash of a vehicle. Airbags, brakes, tires as well as the structure of the car play very important roles during a crash event to deaccelerate or absorb energy from the crash and protect the passenger. Passive and active safety systems in the car can be accounted for/modeled in FEA to evaluate the accurate performance of a car during a crash.

- Noise and Vibration: Characteristics of noise and vibration in a car determines the comfort of a passenger while traveling in a car. Natural frequency, steady-state dynamics, transient dynamics, random response analysis can be studied in Abaqus to characterize the noise and vibration performance of the car accurately.

- Strength & Durability: Durability engineering solutions help deliver lighter, stronger, and more durable designs. Lighter design leads to a more efficient vehicle, stronger and more durable design avoids any premature failure and warranty issues.

Best-in-class companies are taking advantage of Abaqus Unified FEA to consolidate their processes and tools, reduce costs and inefficiencies, and gain a competitive advantage. It considers real-life scenarios to predict what is going to happen when the product is used in reality. It tells you whether a product will break, wear out, or survive for the designed life.

VIAS, in partnership with Dassault Systemes, can be your facilitator in this transformation process – be it consultancy, sales, and support, or training – we have it all. With a dedicated team of Doctorates and master’s having strong expertise in Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG), data analytics, and domain knowledge of various engineering streams, we can handle simple to complex workflows. We have strong expertise in dealing with both mitigation and life extension achieved by following the procedures given for fitness-for-service (FFS) in ASME FFS-1/API-579 within an integrity or risk reliability management framework.

Contributed by:

Raghavendra Banchhor

[email protected]