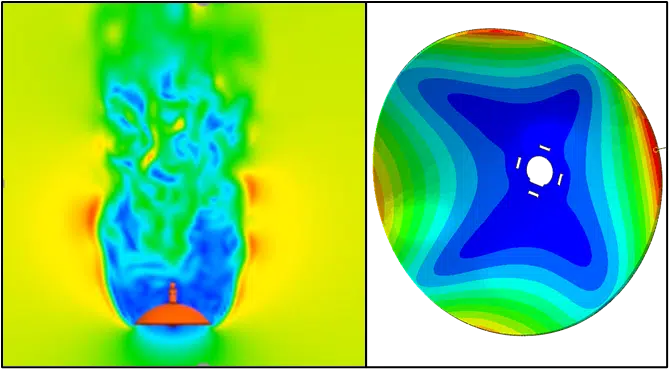

We developed our expertise in computational fluid dynamics (CFD) through solving many real-life engineering flow and thermal applications for different industries, including energy, CPG, medical, appliances, aerospace, automotive, to name a few. We can solve several advanced physics applications such as:

CFD stands for Computational Fluid Dynamics, a numerical approach used to simulate and analyze fluid flow, heat transfer, and other related phenomena in various applications. CFD involves solving mathematical equations that govern fluid behaviour, such as the Navier-Stokes equations, using numerical methods on a computational platform. There are several types of CFD solvers available, including Finite Difference, Finite Volume, Finite Element, Lattice Boltzmann, Smoothed Particle Hydrodynamics, Reynolds-Averaged Navier-Stokes, Large Eddy Simulation, and Multiphysics solvers. The choice of solver depends on factors like the problem’s nature, geometry, and desired accuracy. This flexibility enables engineers and researchers to select the most suitable solver for their specific simulation requirements.

CFD (Computational Fluid Dynamics) is a highly valuable tool for product development, as it enables engineers to virtually simulate and analyze fluid flow and heat transfer within products or systems. This CFD consulting services leads to optimization of designs, early issue detection, safety assessments, cost reduction by reducing the need for physical prototypes which significantly enhances the product development process, resulting in improved performance, efficiency, and reduced time-to-market.

CFD complements experimental testing by offering cost-effective, rapid, and detailed simulations of fluid flow and heat transfer. It allows engineers to explore design variations, study complex phenomena, and identify critical areas for testing. CFD can be used as a preliminary tool, enhancing safety, and validating experimental data, making it a valuable companion to physical testing in various industries.

To ensure the reliability of CFD results, rigorous verification and validation processes are crucial. This involves comparing CFD simulations with analytical solutions or experimental data, selecting appropriate turbulence models, refining grids, and accurately specifying boundary conditions and fluid properties. Conducting sensitivity analyses and documenting assumptions are also essential steps.

CFD (Computational Fluid Dynamics) significantly contributes to carbon footprint reduction by optimizing energy efficiency in buildings, vehicles, and industrial processes. CFD consulting services support the development and enhancement of renewable energy systems such as wind turbines and solar panels, promoting sustainable energy production. Additionally, it enables green building practices by optimizing ventilation and HVAC systems to minimize energy consumption.

Fluid-Structure Interaction (FSI) simulations are crucial for studying the dynamic interplay between fluids and adjacent structures in various applications. They enable realistic modelling, aiding in the assessment of structural integrity and optimization of designs. FSI plays a pivotal role in aerospace, automotive, energy, biomedical, and environmental fields, contributing to safer and more efficient designs while providing insights into the impact of fluid dynamics on diverse systems and structures.

CFD (Computational Fluid Dynamics) is helpful in thermal management by providing a powerful tool for simulating and analysing heat transfer and airflow within these systems. It allows engineers to model and optimize cooling mechanisms, heat sinks, and insulation to efficiently dissipate heat, maintain proper temperature levels, and prevent overheating issues. CFD simulations enable the design and improvement of thermal management solutions, ensuring the reliability and longevity of equipment in various industries, including electronics, automotive, aerospace, and energy.

16000 Park Ten Place,

Suite 301, Houston, TX 77084.