Vehicle aerodynamics design is a critical task when it comes to the fuel efficiency of the car. Especially in when looking at the new electric vehicle industry, it is essential to improve the aerodynamics of an electrical vehicle.

Aerodynamic design typically begins with the earliest concepts of the vehicle based on its shape and size. As the exterior shape is refined, the aerodynamic efficiency is driven by shape parameters such as angles, radii, and dimensions. Typically, you can make improvements in these parameters, however, the challenge faced by vehicle manufacturers is on how to improve the electric vehicle design with minimal impact on the style and aesthetics of an electrical vehicle.

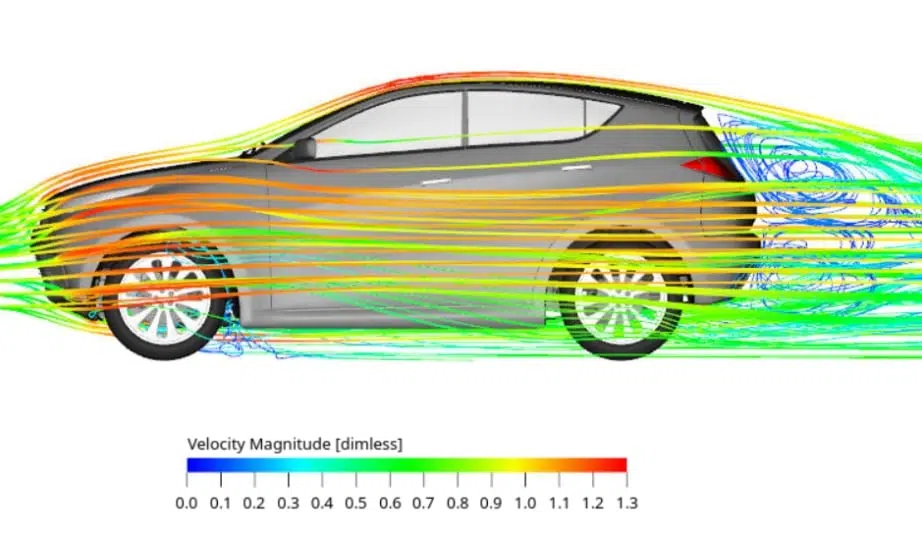

Aerodynamics simulation can help with vehicle development process by reducing both vehicle development costs and design cycle time. Due to its powerful advantages over physical testing methods, simulation can bring much more information about the design performance of an electrical vehicle, improving the ability for designers and engineers to innovate in balancing design aesthetics with aerodynamics. Simulation is more accurate than physical testing because of its ability to capture small details that might not be present on a physical reduced-scale model during the early design stage, and its ability to duplicate actual road conditions without interference from the wind tunnel walls and floor. Not only that, but physical testing can lead to costly mistakes and delays due to accuracy problems that simulation does not encounter. Finally, simulation can reduce the cost of the final vehicle by revealing design improvements earlier in the design phase that do not require additional parts and expense.

PowerFLOW is uniquely designed to bring realism into aerodynamics simulation and is heavily validated across the entire ground transportation industry to bring high accuracy and the confidence required for design decisions. [1]

About VIAS3D

VIAS3D engineering and simulation team combines decades of analytical and design experience. We have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modeling techniques such as Finite Element Analysis (FEA) using Abaqus, Computational Fluid Dynamics (CFD), and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.

To learn more about our technical capabilities in transportation and mobility industry, please visit our website https://vias3d.com/services/industry/transportation-mobility/

References:

[1] Dassault Systems. “POWERFLOW FOR AERODYNAMIC EFFICIENCY” from https://www.3ds.com/products-services/simulia/products/powerflow/applications/aerodynamic/aerodynamic-efficiency/