Electric Vehicles (EVs) are becoming part and parcel of everyone’s life, whether it’s electric scooters, bikes, or cars. EVs offer numerous environmental and economic benefits, like reduced use of fossil fuels, lower operating costs, and various tax benefits granted by the government to EV owners. Still, due to its maturity level, it also poses a significant challenge in terms of safety. Ensuring the crashworthiness of EVs is indispensable, and predicting it through FEA has become a go-to tool for this concern.

The Automotive Finite Element Analysis industry was valued at USD 1.3Bn in 2022, and it is expected to grow at a CAGR of 9.9% from 2023 to 2031. It is expected to reach a market cap of USD 3.3Bn at the end of 2031. The global electric vehicle market was valued at USD 388.1 billion in 2023 and is projected to reach USD 951.9 billion by 2030, registering a CAGR of 13.7% from 2023 to 2030.

Understanding Crashworthiness

Crashworthiness refers to the ability of a vehicle to protect its riders during any impact or collision. For EVs, the crashworthiness is also about managing their battery pack, which can lead to severe problems when damaged, since it is the “new energy hotspot” (replacing the fuel tank).

FEA in Crash simulations

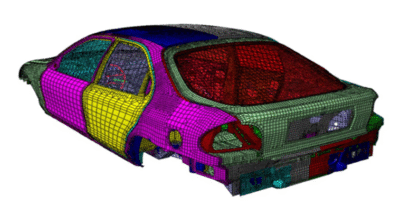

FEA is a numerical method used to simulate and predict how the components of the vehicle (especially the chassis as the main structural component) respond to the external loadings derived from impacts. FEA allows engineers to analyse the behaviour of each part under various scenarios. This detailed analysis is crucial for understanding how an EV will perform in a crash situation.

Some applications of FEA in EV Crash situations

1. Structural Integrity Analysis

Chassis Design: The chassis is the backbone of a vehicle, and it must be designed to absorb and dissipate impact energy effectively. FEA helps us optimize the chassis design, ensuring it is lightweight yet strong enough to protect the riders.

Material Modelling: Using FEA, one can simulate how different materials respond to impacts. Among the material properties used in the FEA model, it is possible to include damage modelling to observe the chain effect of the failure of a component on others. This helps to select materials that offer the best combination of strength, weight, and cost-effectiveness.

2. Battery Pack Safety

Thermal Runaway Prevention: One of the unique challenges of EVs is the risk of thermal runaway in battery packs during a crash. The simulations can perform thermal analysis, including the electric heat generation (Joule effect) in cases of battery pack malfunction provoked by the crash.

Crash protection: FEA is used to design protective structures around the battery pack, ensuring its integrity in collision events, preventing potential fires or explosions.

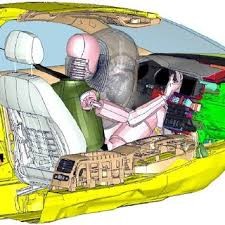

3. Optimizing rider safety

Airbag: FEA allows the simulation of airbag deployment under various crash conditions, so that they deploy correctly and provide maximum protection.

Seatbelt: Simulating the behaviour of seatbelts during a crash helps to design systems that minimize the risk of injury by controlling the deceleration forces experienced by the occupants.

Dummies: It is a sophisticated anthropomorphic test device (ATD) used in vehicle crash testing to simulate the physical responses of the human body during collisions. There are standard FEA dummy models designed to mimic the size, weight, proportions, and articulation of the human body.

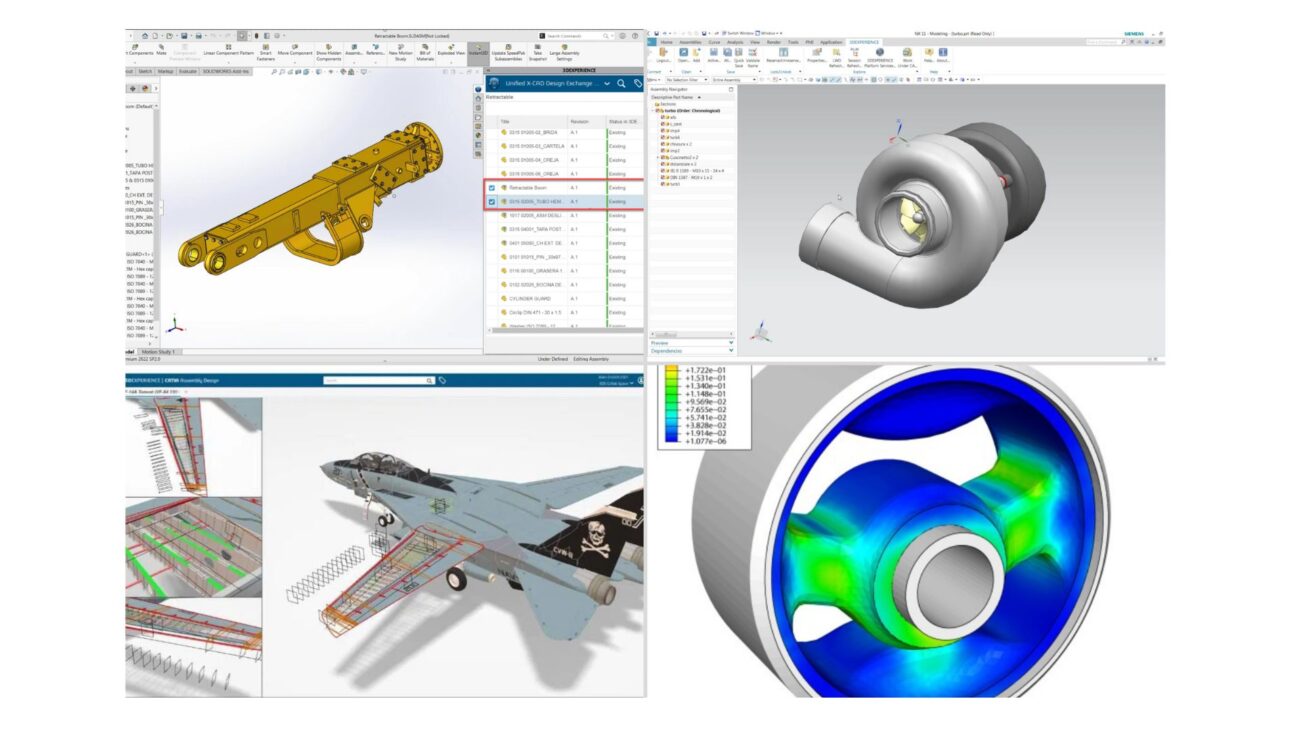

About VIAS3D

VIAS3D engineering and simulation team combines decades of analytical and design experience. They have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modelling techniques such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), Electromagnetics (EMAG), and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought into production.

Please email us at achakraborty@viascorp.com or drop a message at: https://www.linkedin.com/in/arinc16/

Contributors:

Agniva Hazra, B.E Civil Engineering (2025), is an intern at VIAS3D. He is a final year undergrad pursuing his bachelor’s from Jadavpur University (INDIA).

Celso Noronha, Ph.D., the Director of Structural Mechanics at VIAS3D, has extensive experience in the Automotive Industry, allied to his deep knowledge of finite element method fundamentals and applications over decades.

References:-

1. Seham Shahid & Martin Agelin-Chaab, A review of thermal runaway prevention and mitigation strategies for lithium-ion batteries, https://doi.org/10.1016/j.ecmx.2022.100310

2. Transparency Market Research. “Automotive Finite Element Analysis Software Market Size & Share.”

3. MarketsAndMarkets, Electric Vehicle market by component, vehicle type, vehicle class, Propulsion and vehicle drive type. Vehicle top speed and charging point type, vehicle connectivity, end use, region- global forecast 2030