Dassault Systèmes offers several optimization techniques within Abaqus and through its extended solutions. These include:

- Topology Optimization using Tosca Structure for optimal material distribution within a given design space.

- Shape and Size Optimization in Tosca to refine geometry and structural elements for improved performance.

- Design of Experiments (DOE) and Optimization through Isight for exploring design spaces and finding optimal solutions.

- Response Surface Methodology (RSM) in Isight for approximating and optimizing complex functions.

- Sensitivity Analysis in both Abaqus and Isight to assess the impact of various parameters on performance.

These tools enable efficient design processes.

Introduction to Isight:

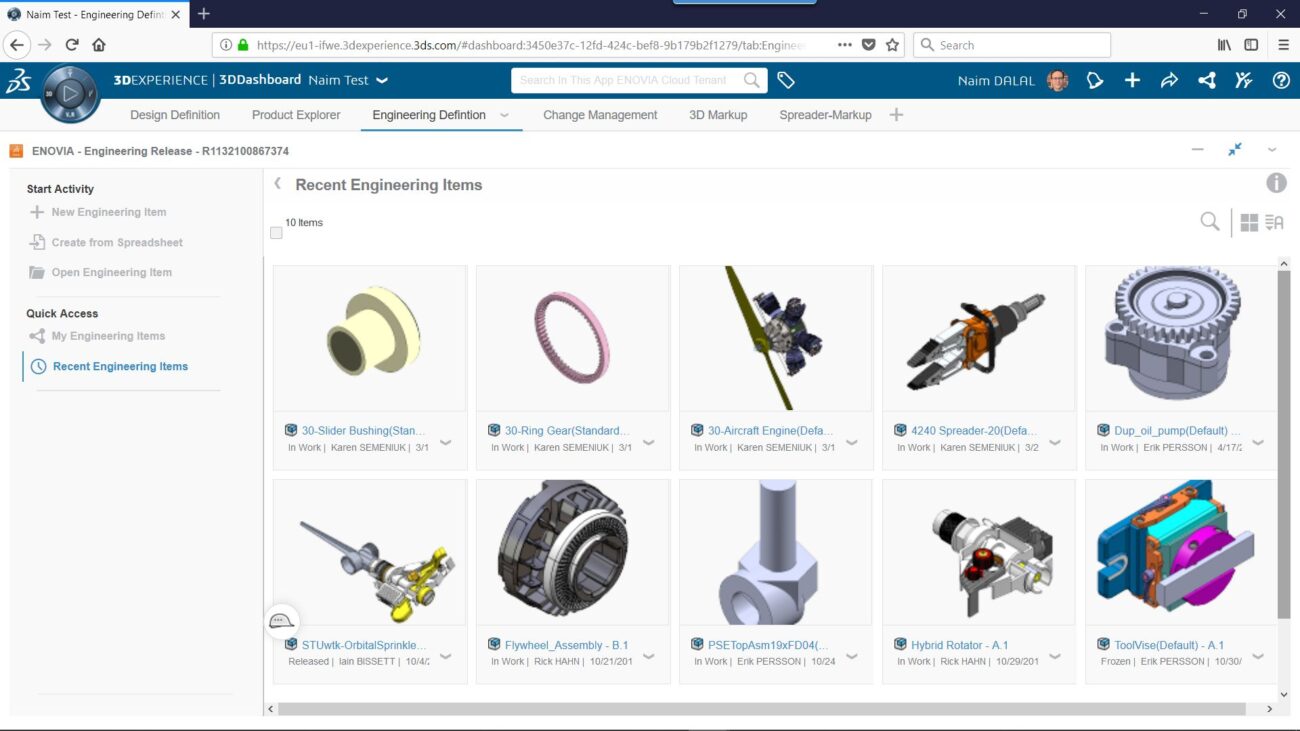

Isight is a powerful process automation and design optimization software developed by Dassault Systèmes. It enables engineers to integrate various simulation tools and automate workflows for performing complex design optimizations, sensitivity analyses, and dynamic design studies. Isight can interface with a wide range of software, including Abaqus, allowing users to create sophisticated multi-disciplinary optimization processes. Its flexibility and user-friendly interface make it a valuable tool in industries where optimizing designs for performance, cost, and efficiency is critical.

Approach to Thickness Optimization of a Container Using Isight and Abaqus:

When optimizing the thickness of a container using Isight and Abaqus, the process generally starts with defining the design objectives and constraints. In this case, the objective might be to minimize the material usage while ensuring that the container meets specific structural requirements, such as strength and durability under various loading conditions.

- Parameterization of the Model: The first step involves parameterizing the container’s geometry in Abaqus, focusing on the thickness as the primary variable. This could involve creating a script or a parametric model where the thickness can be easily adjusted.

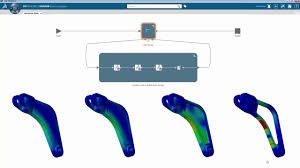

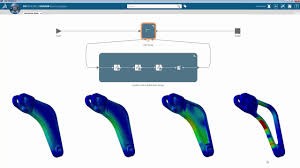

- Creating an Optimization Workflow in Isight: Next, an optimization workflow is created in Isight. The workflow typically consists of multiple components, including the Abaqus model, a design of experiments (DOE) method, and an optimization algorithm. The Abaqus component within Isight is configured to run the simulation for each design iteration, automatically adjusting the thickness parameter.

- Defining Objectives and Constraints: In Isight, you would define the objective function, such as minimizing the container’s weight, and set the constraints, such as maintaining stress levels below a certain threshold. These constraints ensure that the container will not fail under expected load conditions, even as the thickness is optimized.

- Running the Optimization: Once the workflow is set up, Isight runs the optimization process. It evaluates different thicknesses by running Abaqus simulations for each design iteration. The software uses the results to guide the search for an optimal thickness that meets the design objectives while satisfying all constraints.

- Post-Processing and Analysis: After the optimization process, Isight provides a detailed report with the optimal thickness and corresponding performance metrics. You can further analyse these results to ensure the design is practical and meets all requirements before finalizing the container’s thickness.

This approach allows for an efficient and automated way to optimize the container’s thickness, balancing material usage with structural integrity, leading to cost-effective and hardy designs.

Introduction to Tosca Structure:

Tosca Structure is an advanced optimization software developed by Dassault Systèmes, specifically designed for performing topology, shape, and bead optimization. It integrates seamlessly with Abaqus and other FEA solvers to help engineers and designers achieve optimal structural designs by exploring the best material distribution within a given design space. Topology optimization in Tosca Structure allows users to create innovative, lightweight, and structurally efficient designs by removing unnecessary material while maintaining or enhancing performance criteria.

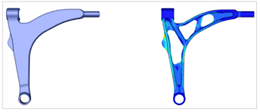

Approach to Topology Optimization Using Tosca Structure: The process of topology optimization using Tosca Structure begins with defining the design space, which is the initial volume where material can exist. This volume is usually a basic, over-engineered shape that encompasses all potential load paths and structural features. The primary goal of topology optimization is to find the most efficient material layout within this design space that meets the performance requirements, such as stiffness, strength, or natural frequency.

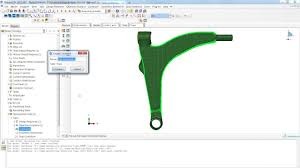

- Model Preparation in Abaqus: The first step involves creating a finite element model of the design space in Abaqus. This model should include all the necessary boundary conditions, loads, and material properties. The design space should be generous enough to allow for material redistribution during the optimization process.

- Setting Up the Optimization in Tosca Structure: After preparing the model, the next step is to define the topology optimization problem in Tosca Structure. This involves specifying the objective function, such as minimizing compliance (which corresponds to maximizing stiffness), and defining constraints like volume reduction, maximum displacement, or stress limits. You also set the manufacturing constraints, which ensure that the optimized design is manufacturable, such as ensuring minimum feature size or symmetry requirements.

- Running the Optimization: Once the problem is fully defined, Tosca Structure iteratively removes and redistributes material within the design space. During this process, Tosca evaluates different configurations to achieve the optimal balance between material usage and structural performance. The software continuously refines the design until the optimization converges on the best solution.

- Post-Processing and Design Interpretation: After the optimization process, Tosca Structure provides a visual representation of the optimized topology. This result often appears as a highly efficient, organic shape that is far different from the original design space. The designer must interpret this optimized topology, possibly refining it further or converting it into a CAD model for manufacturing.

- Validation and Iteration: Finally, the optimized design is validated through further finite element analysis to ensure it meets all design requirements under real-world conditions. If necessary, the process can be iterated by adjusting the design space or optimization parameters to fine-tune the results.

Topology optimization using Tosca Structure allows engineers to push the boundaries of design, leading to innovative, high-performance structures that are lightweight and efficient, ultimately reducing material costs and improving product performance.

About VIAS3D

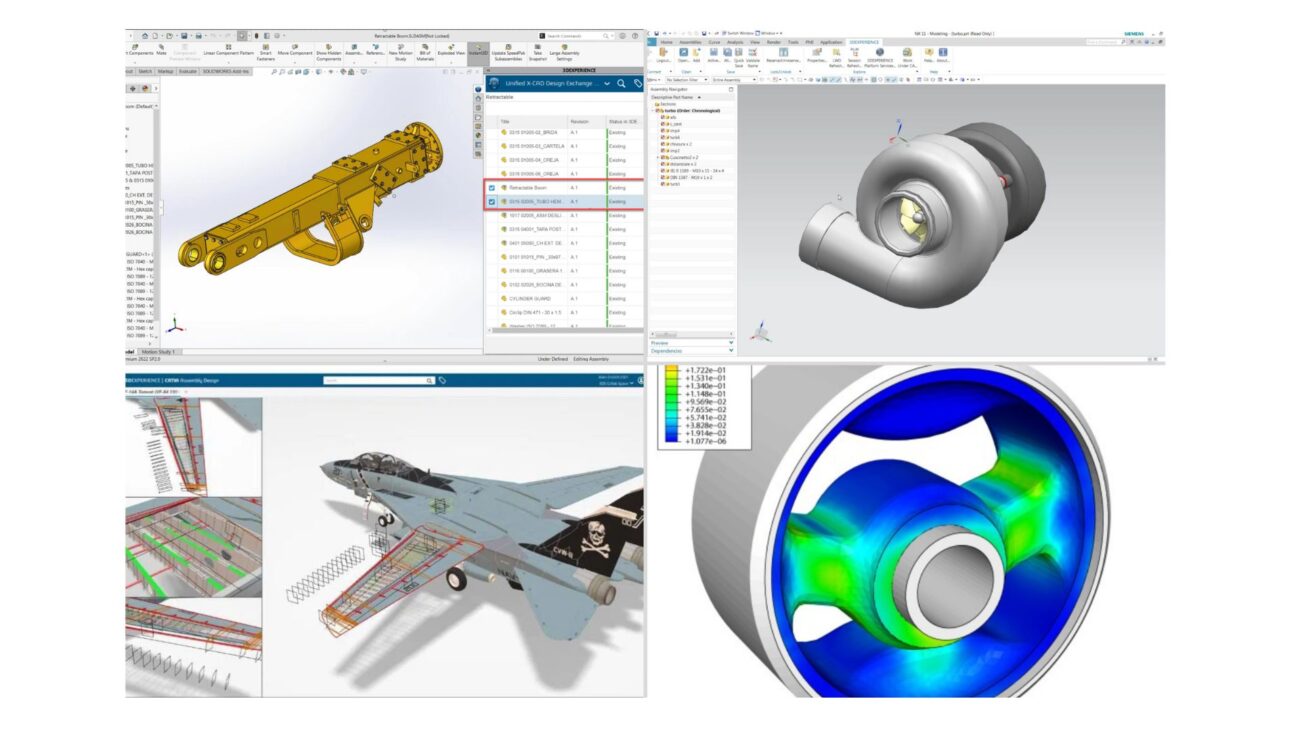

VIAS3D engineering and simulation team combines decades of analytical and design experience. We have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modeling techniques such as Finite Element Analysis (FEA) using Abaqus, Computational Fluid Dynamics (CFD), and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought in production.

Please email us at achakraborty@viascorp.com or drop a message at: https://www.linkedin.com/in/arinc16/

Contributors:

Agniva Hazra, B.E Civil Engineering (2025), is an intern at VIAS3D. He is a final year undergrad pursuing his bachelor’s from Jadavpur University (INDIA).

Celso Noronha, Ph.D., the Director of Structural Mechanics at VIAS3D, has extensive experience in Optimization and Automation, allied to his deep knowledge of finite element method fundamentals and applications over decades.

Reference

- Dassault systemes website, 3ds.com/products/simulia/tosca/structures

- Dassault systemes website, 3ds.com/products/simulia/isight/