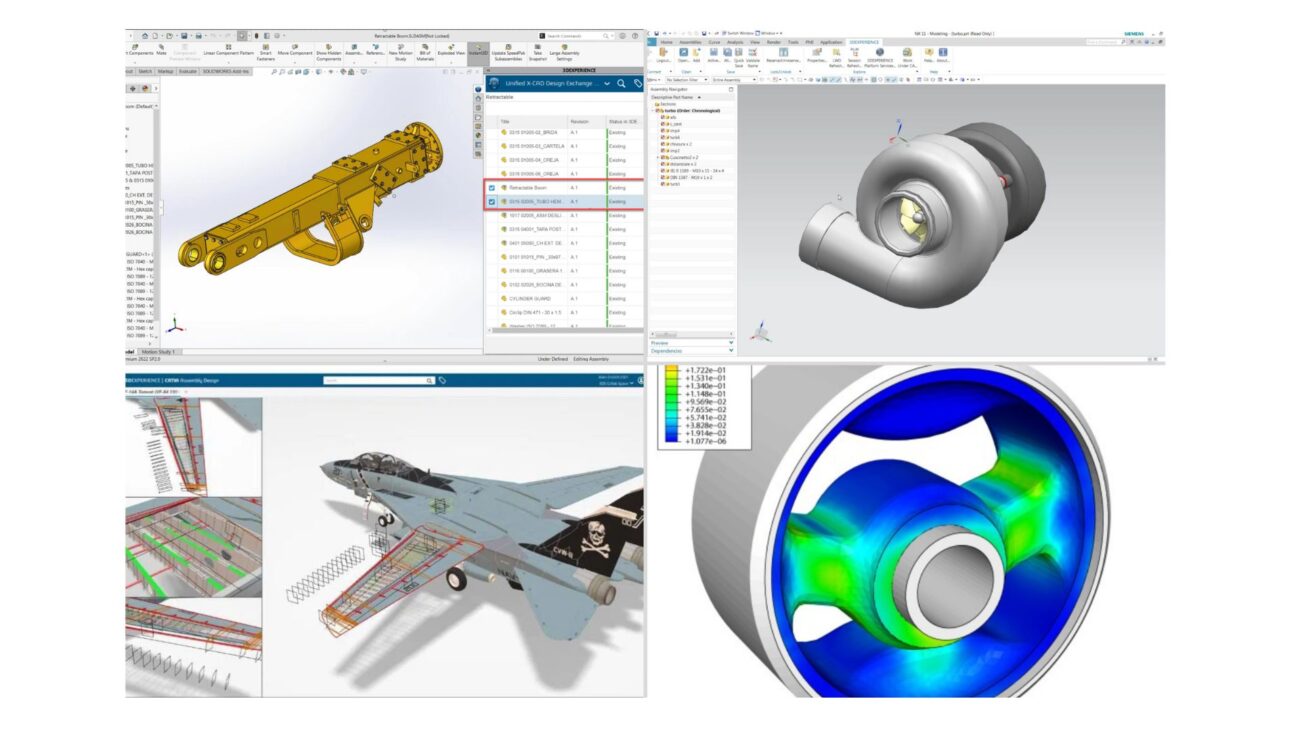

The oil and gas industry faces harsh engineering challenges for offshore production systems, since it involves high pressures and temperatures associated with the subsea environment. The design of the offshore system is also very sensitive, requiring high precision to bring reliability to all single components; otherwise, a failure in a subsystem could lead to catastrophic consequences for the ecosystem. In this sense, engineering simulation through finite element analysis (FEA) and computational fluid dynamics (CFD) is essential to balance the required safety and cost-effectiveness for all offshore production system projects.

Oil & Gas Disciplines

An offshore upstream system is highly multidisciplinary, gathering distinct subsystems to bring the hydrocarbon from the reservoir to the refinery. Each discipline has its engineering team focused on designing that subsystem. Naturally, FEA and CFD simulation play an important role in covering all types of engineering assessments for all different physical problems from the disciplines and, therefore, from the entire offshore production system. It follows a short description of how simulation is used in the main upstream disciplines in a bottom-up overview, followed by a summary table listing a few examples of typical applications for each of them:

- Reservoir: Simulation of numerical models for the flow of fluids through porous formations in the reservoirs where the hydrocarbons are trapped, replicating how these fluids move and interact within the reservoir over time, under various production and injection scenarios. In this sense, simulation enables engineers and geoscientists to gain a deeper understanding of reservoir dynamics from before drilling the first well to tracking reservoir performance over time, identifying bypassed oil, and planning interventions such as infill drilling or enhanced oil recovery (EOR) operations.

- Wells: Simulation is widely used to ensure safety, integrity, and performance throughout the life of the well from design and installation to production. Geomechanics mixed with structural mechanics analysis is performed to evaluate the stability of the wellbore, accounting for powerful numerical features to consider the soil-structure interaction on the strings of the well system.

- Subsea Equipment: The design of the equipment set on the seabed is tremendously assisted by simulations. The code-based analysis is performed by modelling from the flange level to the entire structure. It covers not only the structural strength of the equipment, but also their functionalities like sealability, connection mechanisms, foundation stability, and thermal insulation.

- Subsea Umbilicals, Risers, and Flowlines (SURF): The risers and pipeline design of the subsea system are treated as a very sensitive discipline since it is the longest system of barrier between the production fluid and the subsea environment and, differently of the other disciplines, with no redundant barrier. Therefore, simulation is largely used targeting flawless designs for handling bending, tension, compression, torsion, corrosion, erosion, buckling, and fatigue scenarios on the SURF system.

- Topside: The production unit is a floating factory with engineering design needs like any regular onshore Plant. The harsh offshore environment includes engineering challenges like corrosion (salty humidity), vessel motion (storms), logistics, repairs (far from suppliers), etc. Floating Production, Storage, and Offloading (FPSO), for example, is a vessel loaded with inflammable fluids under such conditions. Numerical simulation is essential to lead with physics of the most critical engineering problems of this discipline.

The simulations support all disciplines independently of the stage of the offshore production system: from the greenfield (conceptual, pre-FEED, FEED, and detailed engineering phases), to brownfield (life extension, engineering critical assessment – ECA, integrity management, fitness-for-service – FFS, decommissioning). Hence, the benefits of the usage of simulations improve the efficiency of the entire system, reflecting on all economic metrics like CAPEX and OPEX.

About VIAS3D

The VIAS3D engineering and simulation team combines decades of analytical and design experience. We have successfully helped to design various products from many industries for strength, stability, rigidity, and fatigue endurance. Our design and analysis capabilities are accomplished through advanced engineering modeling techniques such as Finite Element Analysis (FEA) using Abaqus, Computational Fluid Dynamics (CFD), and other tools.

Using these advanced tools, we can capture complex design features and nonlinearities arising from materials, geometry, and surface interactions to simulate designs and predict their response before they are brought into production.

Please email us at achakraborty@viascorp.com or drop a message at: https://www.linkedin.com/in/arinc16/

Contributors:

Celso Noronha, Ph.D., the Director of Structural Mechanics at VIAS3D, has extensive experience in the Oil & Gas Industry, allied to his deep knowledge of finite element method fundamentals and applications over decades.