Additive Manufacturing Services

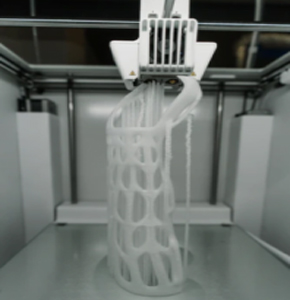

Additive manufacturing (AM) technology has already gained popularity for designing complex geometric structures and easy manufacturability. These technologies are now becoming more cost-effective day by day in a variety of industries. AM can help with completely new innovative design changes for an existing model and improve production efficiency with optimized design and efficient customization.

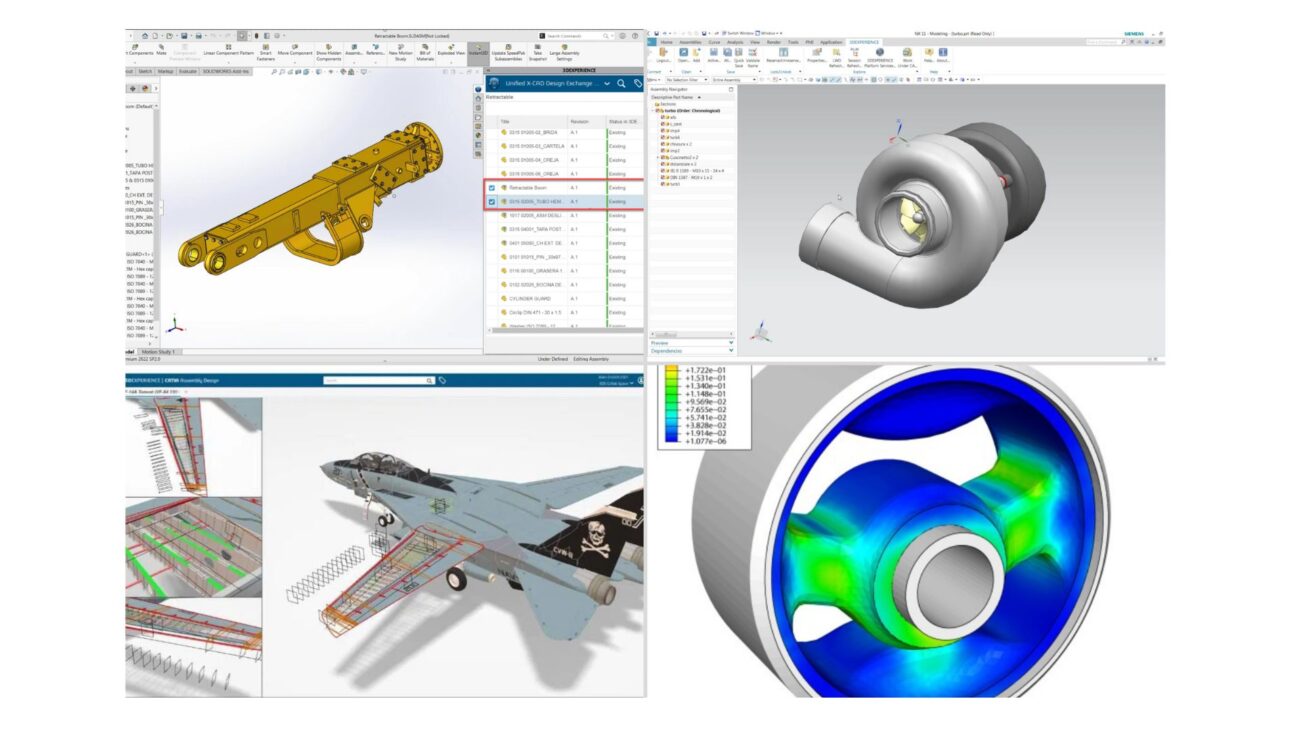

With an in-depth theoretical knowledge and multiple years of experience in AM simulation, we can provide simulation support for:

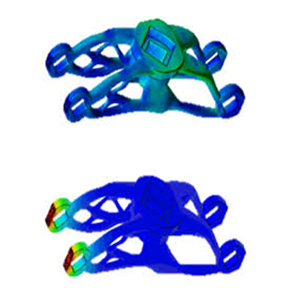

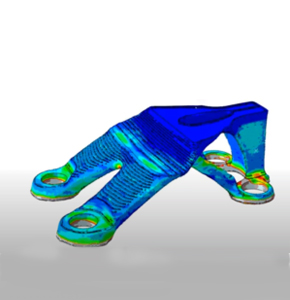

Structural analysis

Thermal, static, dynamic and coupled analysis, residual stress, crack

propagation and fracture modeling,

in-build crack propagation, recoated interference

propagation and fracture modeling,

in-build crack propagation, recoated interference

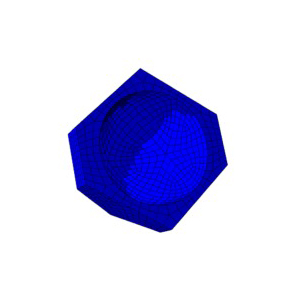

Material modeling

Calibration, nonlinearity, user-specific material, evolution, performance, multi-scale lattice downscaling/ upscaling (material properties via fe homogenization, grain morphology)

Manufacturing Industries: Concept driven designs (thermal and residual stress), heat treatment, machining

Bio-medical implant/ devices: Patient specific design, customer-specific materials, sophisticated and complex geometry (spinal cage, bone)