Aerospace & Defense Services

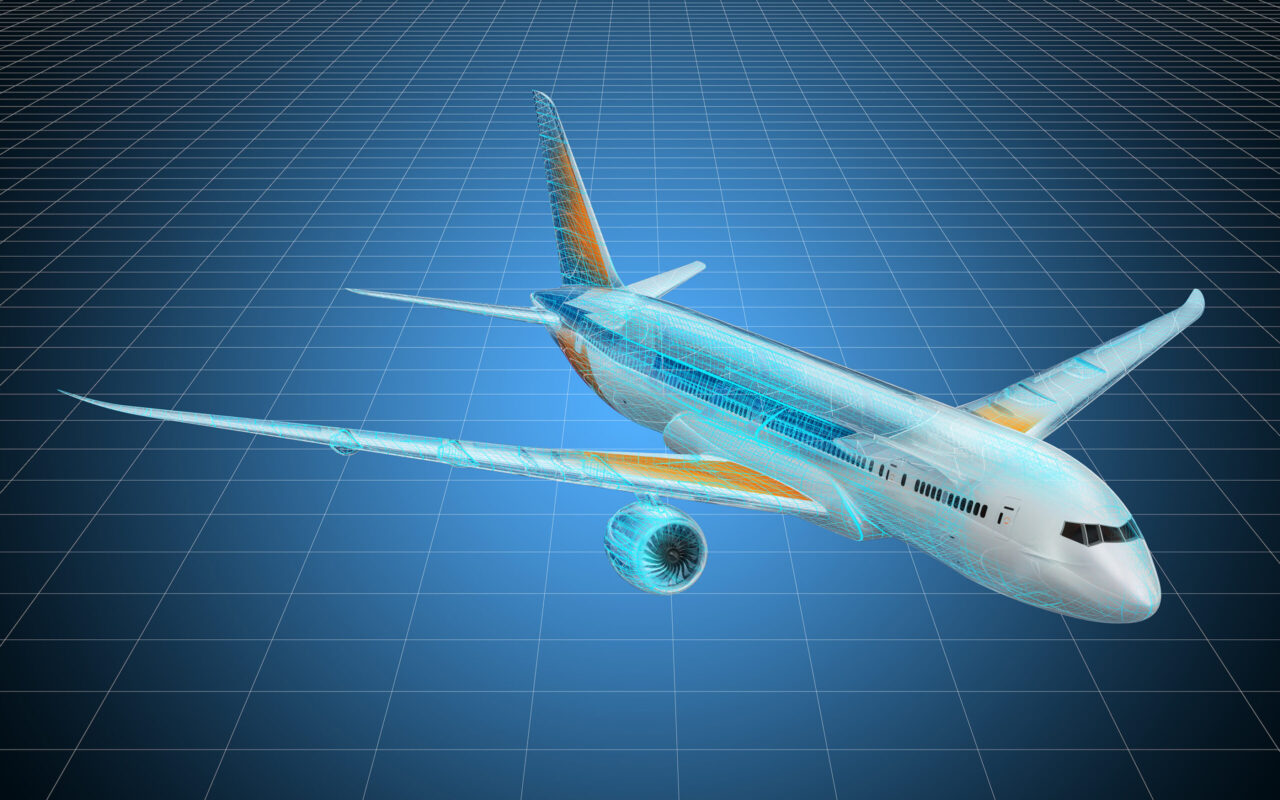

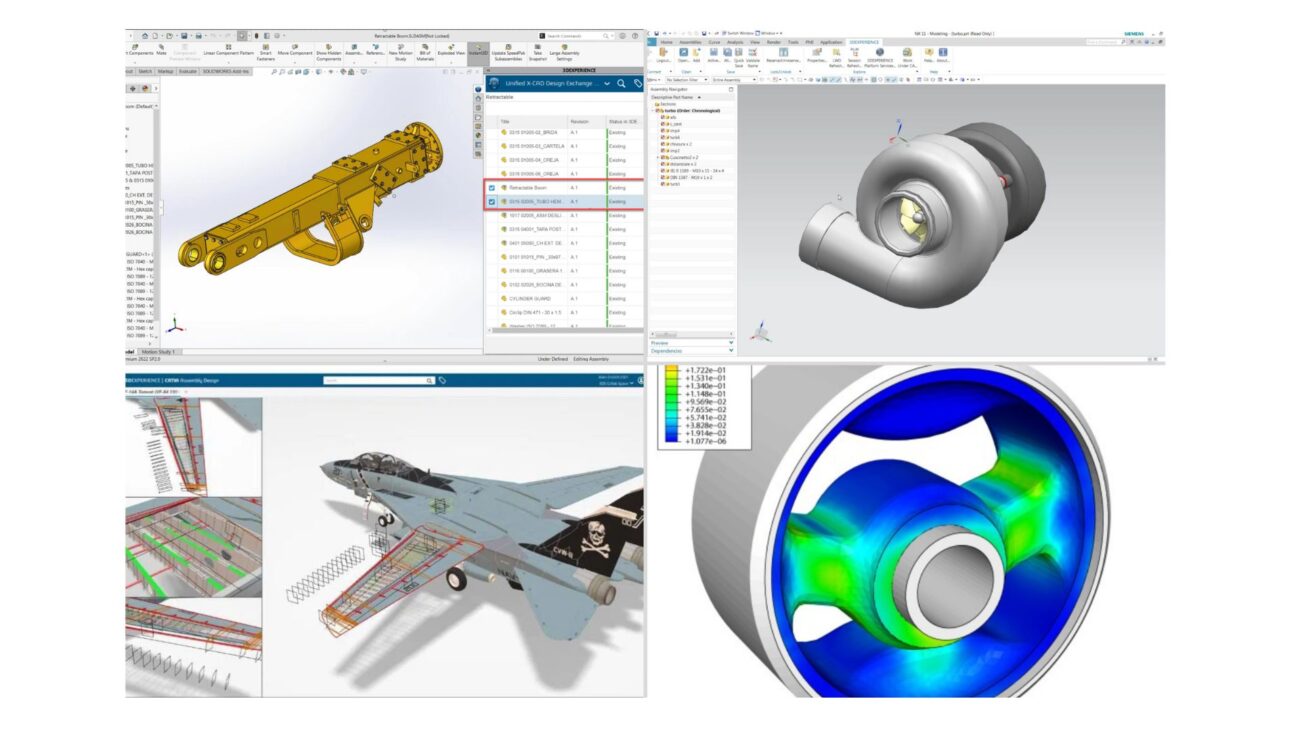

With years of experience in handling highly nonlinear problems, coupled thermal-structural analyses, flow problems, multibody simulations pertaining to aerospace and defense applications from subsonic to transonic speed flows and electrical/electronic systems, our simulation team can help in reducing the cost for physical prototyping, shortening the go-to-market times, improving the product design and to meeting the requirements of the aircraft certification process.

FEA

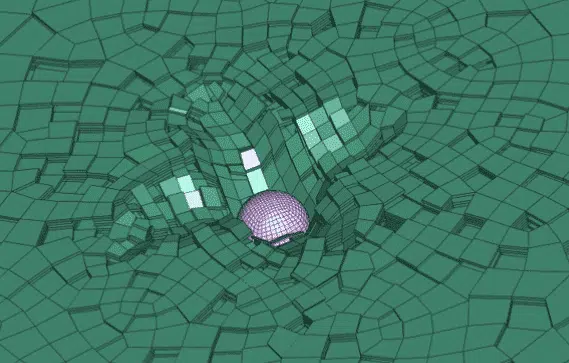

- Aerostructure, Spacecraft and Satellites: Concept analyses and design verification, structural validation at subsystem level (aircraft certification)

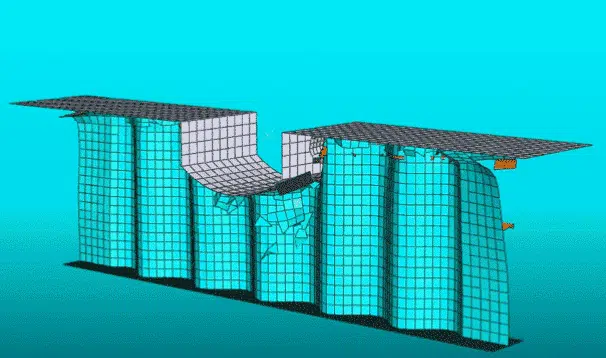

- Composite Structures: Laminate damage, crack propagation, progressive damage modeling, BVID (Barely Visible Impact Damage), optimization of aircraft winglet

- Ballistic Events: Impact dynamics and blast analysis, bird-strike simulation

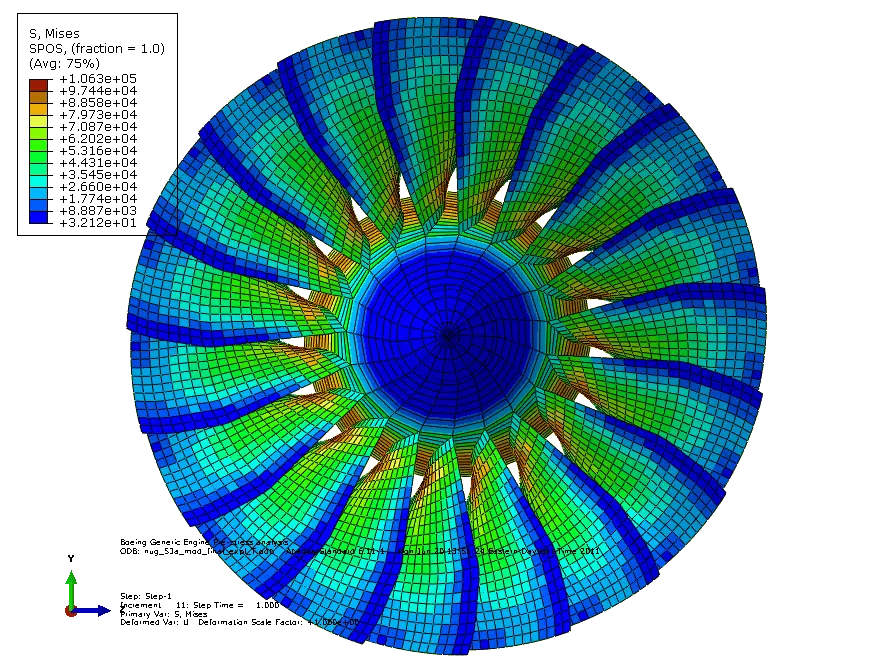

- Aeroengines: High temperature (weld-joint analysis), creep, and wear

- Landing gear: Vibration, contact, friction failure analysis

CFD

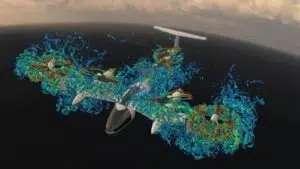

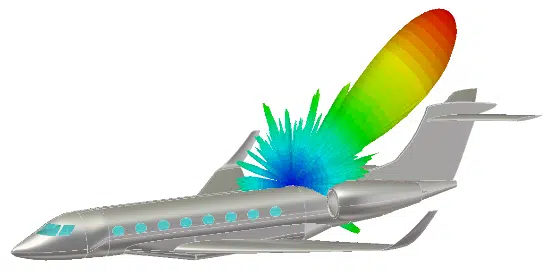

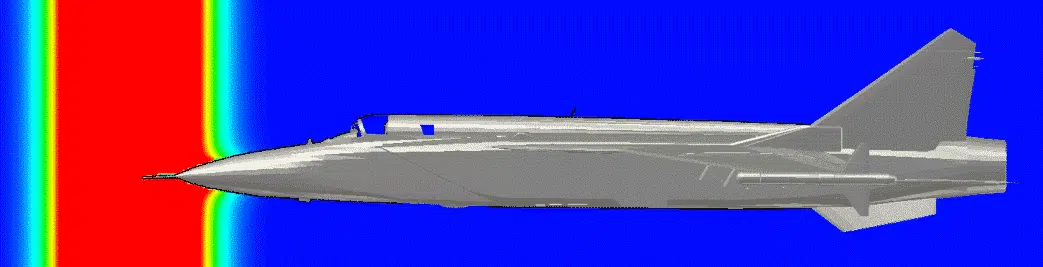

- Aerodynamics: Aerofoils, wing-design, wing-body fairing design, drag prediction, stability and control, aero loads generation, VTOL, UAV

- Thermal Management: Cabin comfort, ECS inlet design, nozzle and avionics cooling, ventilation, heat exchangers, fan performance, conjugate heat transfer

- Propulsion: Propellers, nacelle design, inlet of engine design, thrust reverser, nozzle design, jet engines, rocket motors, combustor design

- Aeroacoustics: Cabin acoustics, noise control (landing gear, wing, cavity, propeller, and fan), jet-screech

- Fuel Systems: Fuel delivery systems, fuel sloshing, fuel system design, fuel pumps

- Environmental Control Systems: Engine integration, APU integration, ducting and heat exchangers, ice protection system, fogging and defogging, dust accrual

- Fluid-Structure Interaction (FSI): Aeroelastic prediction, wing flutter, dynamic fluid body interaction

EMAG

- Communication & Detection: Antenna/antenna array design, installed performance, co-site interference, radome design, Radar cross-section analysis

- System Electromagnetic: Lightning-strike protection, HIRF and EMP

- Components Design: MW&RF components, 2D and 3D filters, tunning/optimization, Multiphysics analysis, RF vacuum breakdown, Ionization breakdown

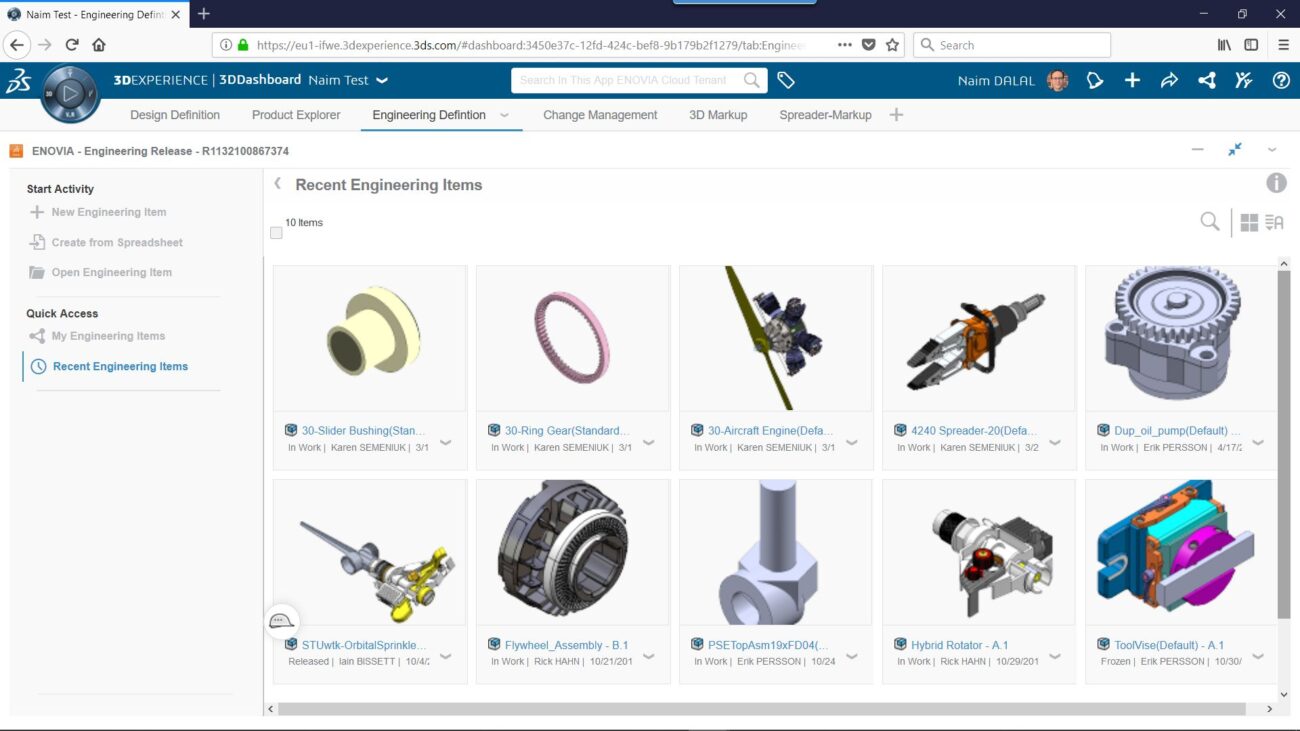

Challenges faced by the industry include:

- Rebuilding Passenger Confidence

- Driving Down Costs

- Enabling Flexible Production

- Transforming the Supply Chain in the Value Network

- Developing Sustainable Technology and Services

We have experience helping Airframe Original Equipment Manufacturers (OEMs), Aerospace Suppliers, and airports – from ideation to roll out.

Our concentrations include:

- Airport Experience

- Build to Operate

- Cleared to Operate

- Co-Design to Target

- Engineered to Fly

- Keep Them Operating

- Passenger Experience

- Program Excellence

- Ready for Rate

- Reinvent the Sky

- Winning Concept

Related Blogs

03

Apr

The Role of Computational Electromagnetics in Aerospace and Defense

-

Posted by

VIAS3D

Over the years, Computational Electromagnetics became an essential part of the latest developments in the Aerospa...

02

Apr

Simulation for Structural Validation of Aerospace Structures

-

Posted by

VIAS3D

What is Damping? The new age flyers are very sceptical & do not want to compromise on their time…

01

Apr

Using Multi-Physics Simulation for successful Satellite launches

-

Posted by

VIAS3D

Since the 1st satellite launched in 1957, the technology kept evolving & companies are still looking for...