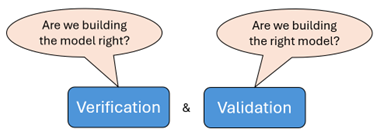

Verification and validation (V&V) in Computer-Aided Engineering (CAE) is very important to ensure reliability and accuracy of simulation models. It establishes that the model simulates the real-life physical situation accurately. Verification process confirms whether the implemented mathematical models and computational algorithms describe the real-life situation correctly whereas validation process determines whether the simulation model represents the real-life situation accurately.

Verification involves error-checking and code validation. It is generally divided into two categories: code verification and solution verification. Code verification ensures that the software solves the model equations as intended. It ensures the correct implementation of the numerical algorithms and correction of any programming errors. An example of code verification is comparison of simulation results with analytical solution. Solution verification procedure checks the results of simulation model for accuracy. It involves estimation and reduction of discretization errors. An example of solution verification is mesh-sensitivity study.

While verification ensures correctness in model building, validation compares simulation results with experimental observations. Validation ascertains that the model behaves as intended under realistic conditions. Validation includes carefully designed experiments that replicate the parameters used and conditions simulated in the model. Differences observed between the simulation results and experimental data are then analyzed to identify potential sources of error which may be a result of model simplifications or inappropriate material properties, boundary conditions etc.

Verification and validation procedure increases confidence in the simulation results and, consequently, predictive capabilities of the simulation model. This is essential for making reliable engineering decisions. V&V also helps in identifying and mitigating errors at early stages of development. However, V&V may be challenging for very complex simulation models which often involve multi-physics or multi-scale phenomena. Sometimes, it may be difficult to obtain high quality experimental data for validation and, thus, quantify uncertainty in models. Therefore, many industries have or are in the process of developing standards and regulations that govern the V&V processes to ensure safety and efficacy.

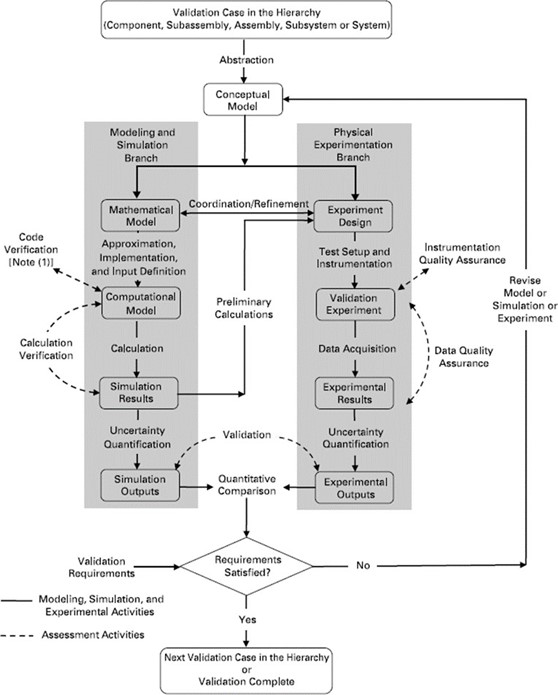

The verification and validation process can be performed at material, component, sub-assembly or assembly level as shown in the figure. The physical experimentation branch determines the experiment, generates data, quantifies uncertainty and provides required data for validation purposes. The modeling and simulation branch determines the numerical model to use, verify the model, perform simulations and provide simulation results for validation purposes. The validation is successful if the requirements on accuracy of simulation model are met.

Engineering Services at VIAS3D is committed to follow Verification & Validation guidelines in all consulting projects that offer support to our clients through physics-based scientific simulations. VIAS3D has developed training on Verification & Validation which has become very popular among various companies and national labs. If you would like to know more about VIAS3D’s consulting and training, please contact Arindam Chakraborty, PhD, PE Email:achakraborty@vias3d.com, LinkedIn:https://www.linkedin.com/in/techarindam/.

Keywords: Verification, Validation, Reliability of simulation models.

References:

[1] ASME Verification,Validation and Uncertainty Quantification Standards,

https://www.asme.org/codes-standards/publications-information/verification-validation-uncertainly

About VIAS3D:

Vias3D delivers integrated engineering solutions using simulation-based design and analysis, data analytics, and material testing for a variety of industries including High-tech, Energy, Life sciences, Utilities, Transportation, and Oil & gas. We bring to our clients dedicated, cost-effective, quick, and safer solutions with an experienced team of simulation experts and industry professionals. Vias3D also provides engineering design, root cause analysis, optimization, project management, operations support, and operations integrity assessment with a combined personnel experience of more than 100 years. It also provides knowledge transfer through customized training.

Contributors:

Vias3D Engineering Services Team

Akshay Dandekar, PhD, PE (OH), Senior Engineer

Dr. Dandekar is a mechanical engineer with more than 5 years of academic and consulting experience in solid mechanics, fracture mechanics, material characterization and finite element analysis. He holds a PhD in mechanical engineering from Purdue University and Master’s in aerospace engineering from the University of Illinois. He is a registered professional engineer in Ohio.