DELMIA

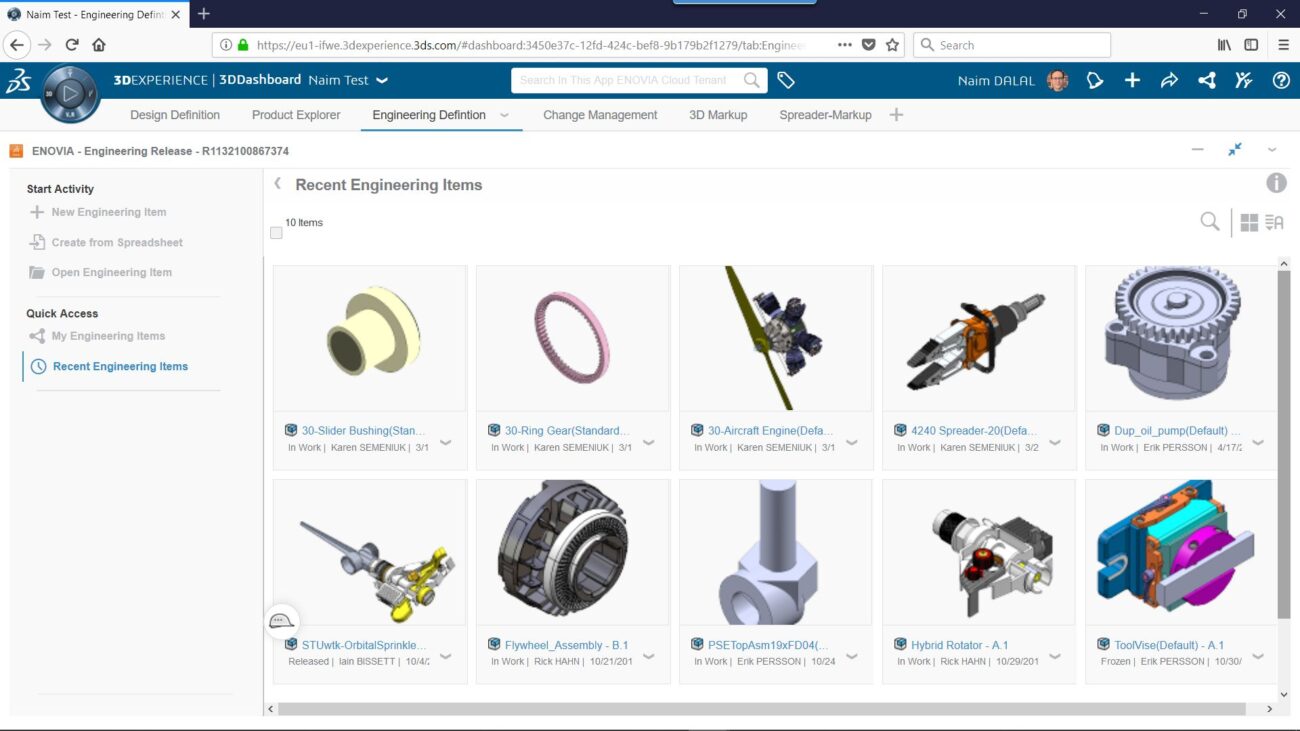

ENOVIA enables you to securely collaborate and innovate together to build and execute a successful plan.

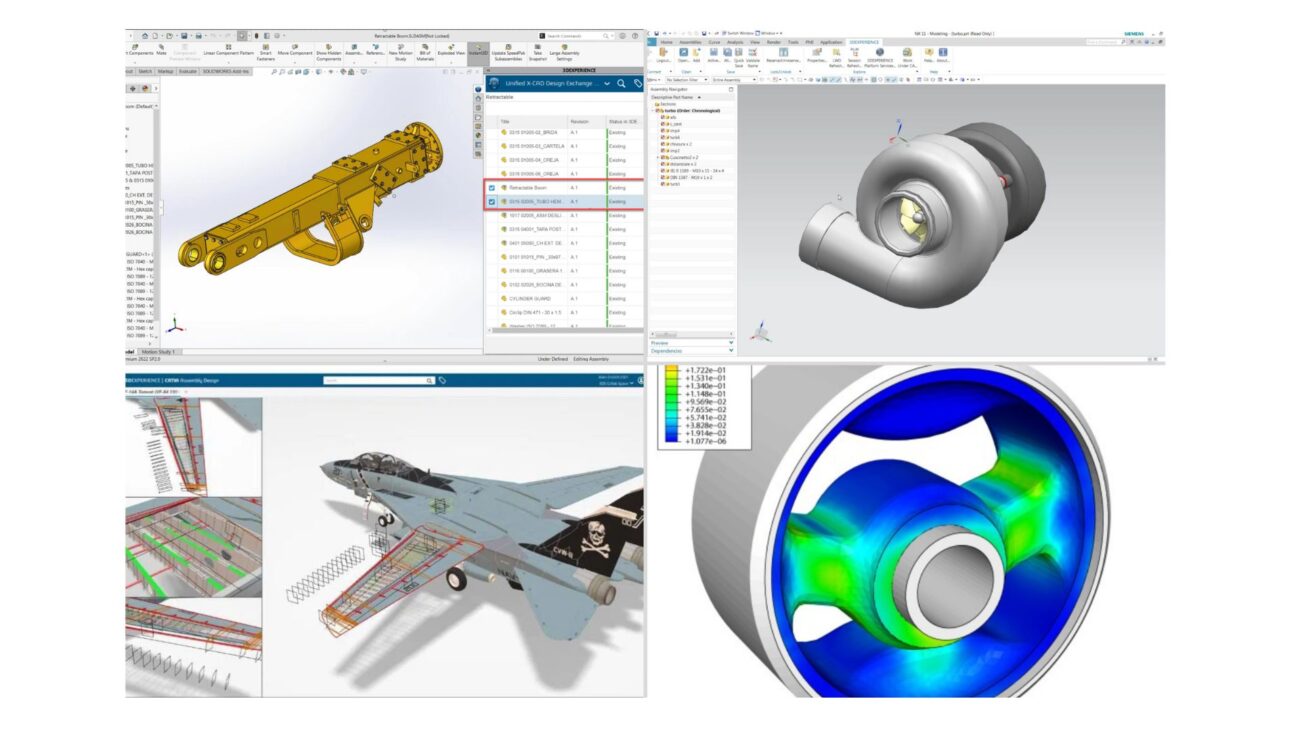

DELMIA is the Digital Manufacturing and Production solution from Dassault Systemes 3DEXPERIENCE platform, optimising production systems and processes . With DELMIA you can design and test in a simulated production environment. Once complete, you can efficiently plan, produce, and manage all resources from staff, to production , to customer.

Robotics

VIAS3D is one of North America’s leading consulting partner to automation integrators, robotics integrators and industrial equipment OEMs for CAD design, FEA, CFD, and Robotics & Plant Optimization.

Our Digital Manufacturing Solutions

Robotics & Plant Simulation and Offline Programming

Choose from over 1500+ robots with pre-defined kinematics to define and validate new work cells with robots efficiently.

- Includes Kuka, Fanuc, Motoman, Yaskawa, Nachi, Mitsubishi, and other major robot families

- Built-In Workflows and PPR contexts to teach robots for Pick & Place, Spot Welding, Arc Welding, and Surface Painting operations

- Reduce on-the-floor programming time

Custom Equipment Design, Simulation, and Analysis

Import CAD as STEP or IGES from any CAD system and define equipment kinematics for custom tooling, machinery, and end-of-tool effectors to accurately conduct cycle time studies, reach studies, and clash.

Virtual Factory Process Simulation

Validate assembly processes and operations for accurate performance estimates.

- Conduct discrete event simulations to validate overall workstation cycle time

- Run multiple iterations of the process to provide accurate and validated cycle time and performance estimates to your customers

- Anticipate bottlenecks and resource timing.

Ergonomics and Work Safety Analysis

- Advanced Ergonomic Design: Create and optimize workstation and product designs to ensure worker comfort and safety.

- Precise Ergonomic Analysis: Perform detailed analyses of postures and movements to identify areas of risk and improve ergonomics in the workplace.

- Prevention of Work-Related Injuries: Prevent work-related injuries, such as musculoskeletal disorders and repetitive motion disorders, by identifying and mitigating ergonomic risks. This helps to reduce costs associated with healthcare, workers' compensation, and lost time due to injuries.

- Regulatory Compliance: Facilitates compliance with health and safety occupational regulations and standards by providing tools to assess and improve ergonomics in the workplace.

- Informed Decision Making: Provides accurate data and analysis to support informed decision-making about workstation design and the implementation of ergonomic measures.

Work Instructions and Report Generation

- Clear and Visual Instructions: Provides clear and visual step-by-step instructions for manufacturing processes, ensuring ease of understanding for operators on the shop floor.

- Customizable Templates: Offers customizable templates that enable businesses to create work instructions tailored to their specific manufacturing processes and requirements.

- Integration with 3D Models: Integrates with 3D models and CAD data, allowing for the creation of interactive and immersive work instructions that provide a realistic view of the manufacturing environment.

- Digital Accessibility: Reduce the reliance on paper-based instructions by enabling access to work instructions digitally and ensuring that operators always have access to up-to-date information.

- Multimedia Support: Supports multimedia elements such as images, videos, and animations within work instructions, enhancing comprehension and reducing errors.

- Version Control and Revision Management: Facilitates version control and revision management of work instructions, ensuring that operators are always using the latest and most accurate instructions.

- Mobile Compatibility: Allows operators to access work instructions from smartphones or tablets directly on the shop floor, increasing flexibility and efficiency.

- Compliance and Quality Assurance: Helps ensure compliance with industry regulations and quality standards by providing standardized and consistent work instructions that promote best practices and quality assurance.

- Training and Onboarding Support: Supports training and onboarding processes by providing comprehensive and easy-to-follow instructions for new operators, reducing the time required for training and improving overall workforce efficiency.

Virtual Reality for Digital Manufacturing

- Immersive Digital Manufacturing Experience: DELMIA provide an immersive digital manufacturing experience, allowing users to visualize and interact with virtual replicas of real-world manufacturing environments.

- Realistic Simulation: Users can simulate and interact with lifelike 3D models of production lines, factories, and equipment, enabling them to test processes, identify optimization opportunities, and troubleshoot issues in a virtual environment before implementation in the real world.

- Enhanced Collaboration: Facilitates collaborative decision-making by allowing multiple stakeholders, such as engineers, designers, and operators, to virtually explore and interact with manufacturing processes together in real-time, regardless of their physical location.

- Intuitive User Interface: DELMIA's VR interface is designed to be intuitive and user-friendly, enabling users to navigate complex manufacturing environments effortlessly and access relevant information and tools seamlessly.

- Cost Savings: Organizations can realize significant cost savings by reducing the need for physical prototypes, minimizing downtime for process optimization, and mitigating risks associated with errors and accidents in the real-world environment.

- Competitive Advantage: Organizations can gain a competitive advantage by accelerating time-to-market, improving product quality, optimizing production processes, and enhancing overall operational efficiency.

- Training and Education: DELMIA's VR capabilities can be used for training and education purposes, allowing users to simulate hands-on tasks, practice operating equipment, and familiarize themselves with manufacturing processes in a safe and controlled virtual environment.

Our Customers

CENTERLINE Limited

Canadian Industrial Automation Process & Technology company CenterLine Limited chose 3DEXPERIENCE Robotics Simulation to realize valuable performance gains.

- Improve project turn-around time by 50%

- Reduced tooling rework by up to 90%

- Reduced on-the-floor programming time by as much as 75%

Prodomax

The Prodomax case study highlights their use of DELMIA for advanced manufacturing simulations in the automotive industry. Key points include:

- Implementing virtual twin technology for efficient production line planning and optimization.

- Improved tool design and cycle times for enhanced production efficiency.

- Quick commissioning and customer satisfaction due to rapid adjustments and setup.

- Cost savings by reducing the need for physical prototypes.

Webinars

Go from CAD to a fully -defined work Instruction with DELMIA on 3DEXPERIENCE

Explore how a simple CAD model can be used to create the MBOM , define manufacturing processes, and define work instruction with 3DEXPERIENCE On-Cloud

Contact Us

Ready to transform your systems engineering processes? Contact us today to learn how our DELMIA services can benefit your organization and lead you toward operational excellence.