Introduction

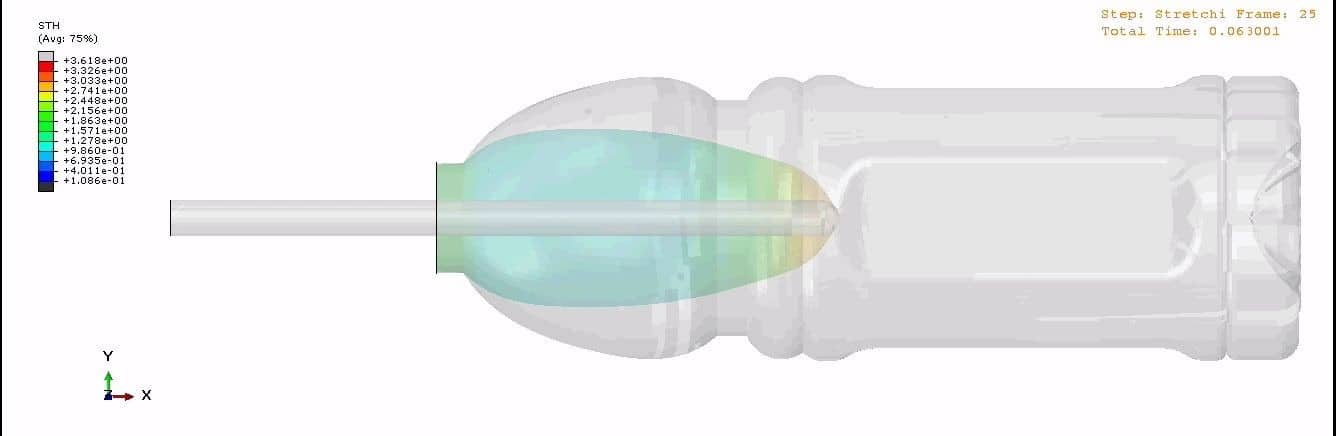

Blow molding is a manufacturing process that is used to create hollow plastic parts by inflating a heated plastic tube until it fills a mold and forms the desired shape. This process is highly economical to manufacture high volume, one-piece hollow objects. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding.

The blow molding process begins with melting down the plastic and forming it into a parison or, in the case of injection and injection stretch blow molding (ISB), a preform. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can pass. The parison is then clamped right into a mold and air is blown into it. The air pressure then pushes the plastic out to match the mold. Once the plastic has cooled and hardened the mold opens up and the part is ejected. Water channels are curved inside the mold to assist in cooling.

Why Virtual Simulation?

Manufacturer often have to design and produce package for a new product within a limited design-to-delivery time and cost. Designers often create innovative concepts, but retreat to conventional shapes due to limited time and resources for physical prototyping and testing.

Simulation enables designers to

- Virtually test new innovative concepts,

- Reduces design time and expensive cost of physical testing,

- Lowers material cost and improves sustainability by light-weighting,

- Reduces damage cost during production and transport by eliminating bad designs quickly,

- Improves confidence in quality by predicting package usage performance.

[KGVID]https://www.viascorp.com/wp-content/uploads/2020/10/Thickness_Change_Animation_1-Converted.mov[/KGVID]

[KGVID]https://www.viascorp.com/wp-content/uploads/2020/10/Thickness_Change_Animation_1-Converted.mov[/KGVID]

Conclusion:

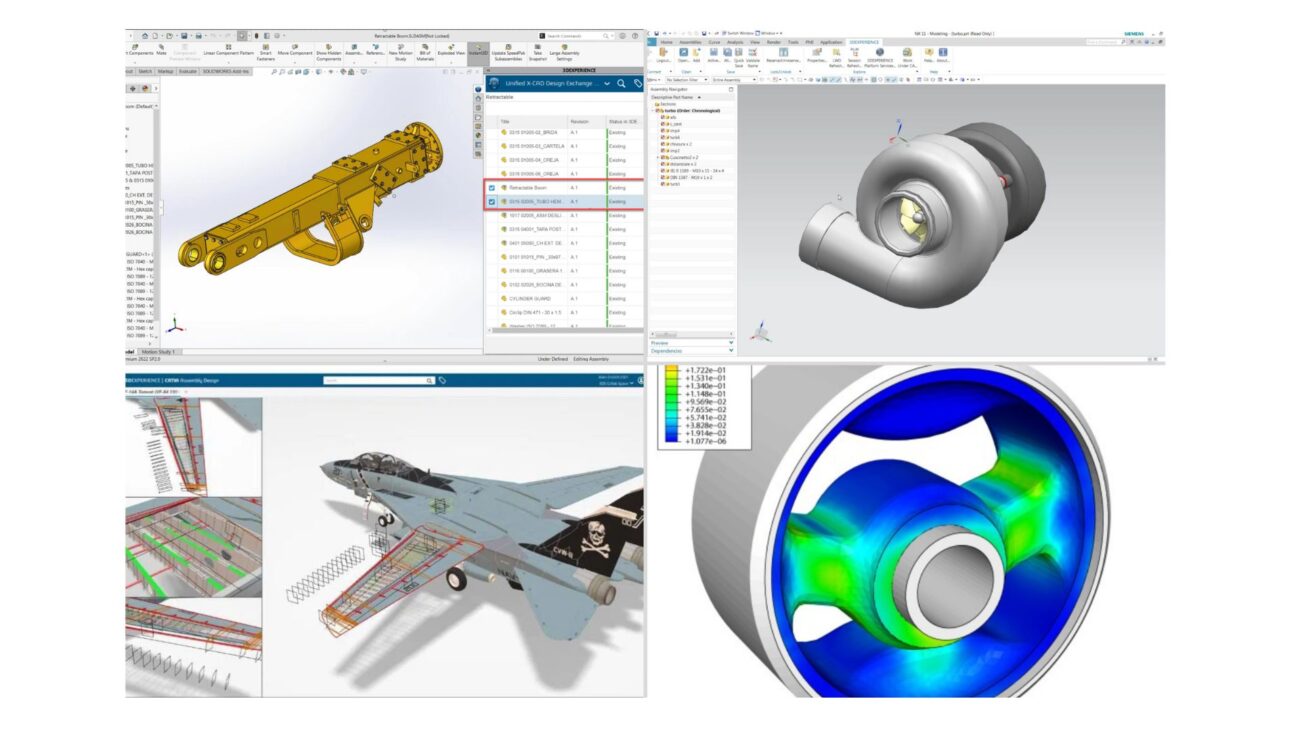

To meet the dynamic, competitive landscape of the consumer packaged goods (CPG) industry to produce a wider variety of top-quality, innovative containers in ever shorter time periods and at lower unit prices SIMULIA Abaqus Unified FEA is one of the best in class numerical package. Abqus explicit solver, automated meshing, complex material characterization library, robust general contact algorithm helps the engineer to confidently design and deliver the new innovative products. The above simulation took few hours to model and simulate the whole blow molding process. The model is just a representative demo of similar kind of simulation. However, this kind of simulations requires lot many parameters to be calibrated with the experimental data for first time to setup the whole process.

If you want to have a better understanding of your product during/after the blow molding process under different loading scenario, please do not hesitate to contact us.

Please email us at [email protected] or drop a message at: https://www.linkedin.com/in/arinc16/

Contributors:

Subhadip Maiti, M.Tech., is a Senior Simulation Consultant at VIAS – He is a Mechanical Engineer with more than eight years of professional experience of strong Industrial and consulting experience in linear and non-linear FEA, structural design & optimization, fatigue and fracture mechanics, noise & vibration analysis, solid mechanics and design etc . He also has a strong background in experimental testing and simulation correlation. Mr. Maiti has worked with multiple consulting/MNC companies in developing simulation workflows, process automation, new product design, SOP for experimental testing etc. He holds Master’s degree in Mechanical Systems Design from Indian Institute of Technology, Kharagpur. He can be reached at [email protected].

References:

1] J. Zimmer, M. Stommel J. Denria, “Method for the evaluation of stretch blow molding simulations with free blow trials”, IOP Conference Series: Materials Science and Engineering.

2] Simulia ebook “Create package designs faster, better and cheaper with realistic simulation”.