Industrial Equipment

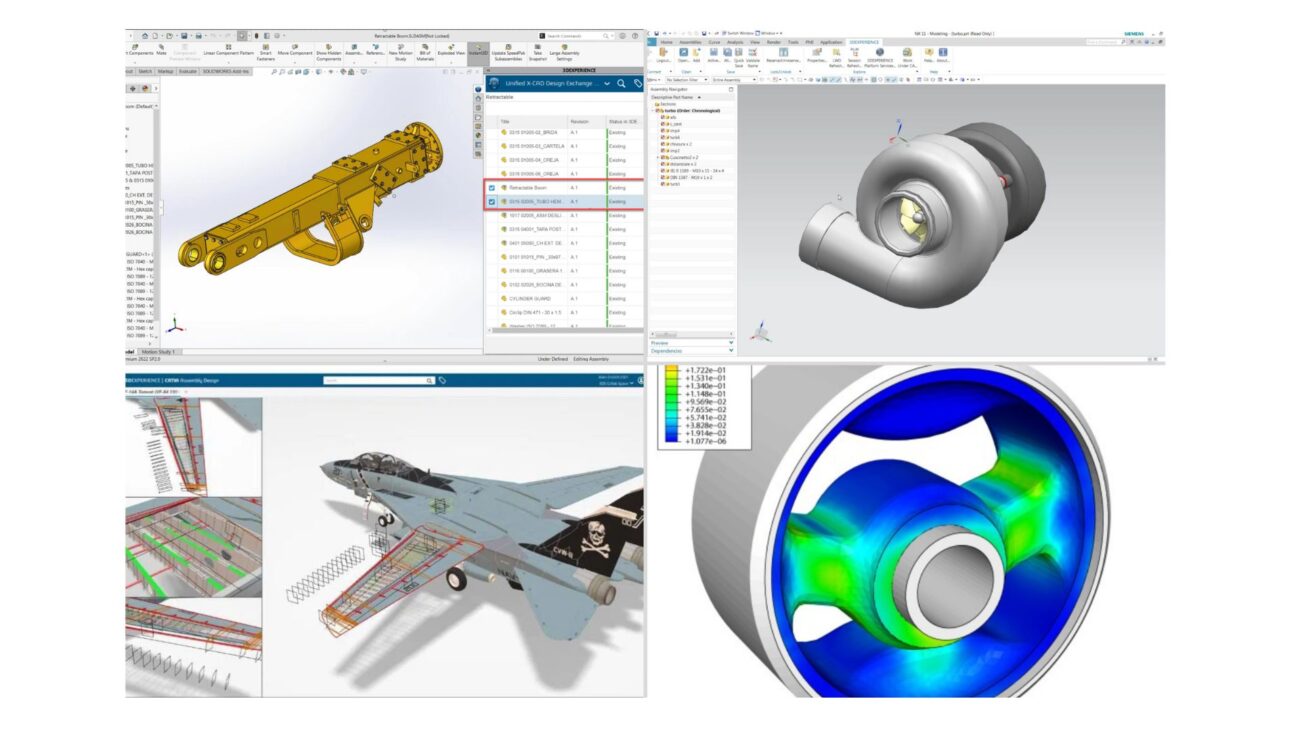

We offer easy-to-use analysis tools to automate the performance of design exploration, Industrial Equipment Integrated engineering solutions using virtual design experience and data analytics for Industrial equipment applications studies and design optimization. Our design team can accurately predict complex real-world behavior of component parts, large scale structures, and complete systems.

VIAS3D provides integrated, innovative, and cost-effective engineering and software solutions to simulate realistic solutions, that address a multitude of engineering challenges for industrial equipment manufacturers.

VIAS3D has simulation and software solutions to help you navigate the biggest challenges in this industry including

Electric, Connected & Autonomous Vehicles

New Customer Experience

Quality, Regulations, Cost

Mass Production to Mass Customization

Produce and Teach Robotic Applications efficiently with Digital Equipment Continuity

Import CAD from Solidworks, CATIA, or any other CAD source to quickly prototype 3-dimensional plant layout variations with over 1500+ robots and custom-defined equipment to define robot behavior with different applications:

Validate Overall Work Cell Performance

Instantiate multiple robots, conveyors, custom tooling, and human interactions to simulate the complete automation solution over multiple iterations to calculate key performance indicators such as overall cycle time, reach studies, time studies, safety zones, and resource idle times.

Validate Offline Programming and Virtual Commissioning with the Line Builder Industry Portfolio

With the combination of CATIA Control Build and 3DEXPERIENCE Virtual commissioning, validate work-cell responses, train personnel, and test the complete line before authorizing production to reduce expensive reworks and mistakes during final build and delivery.

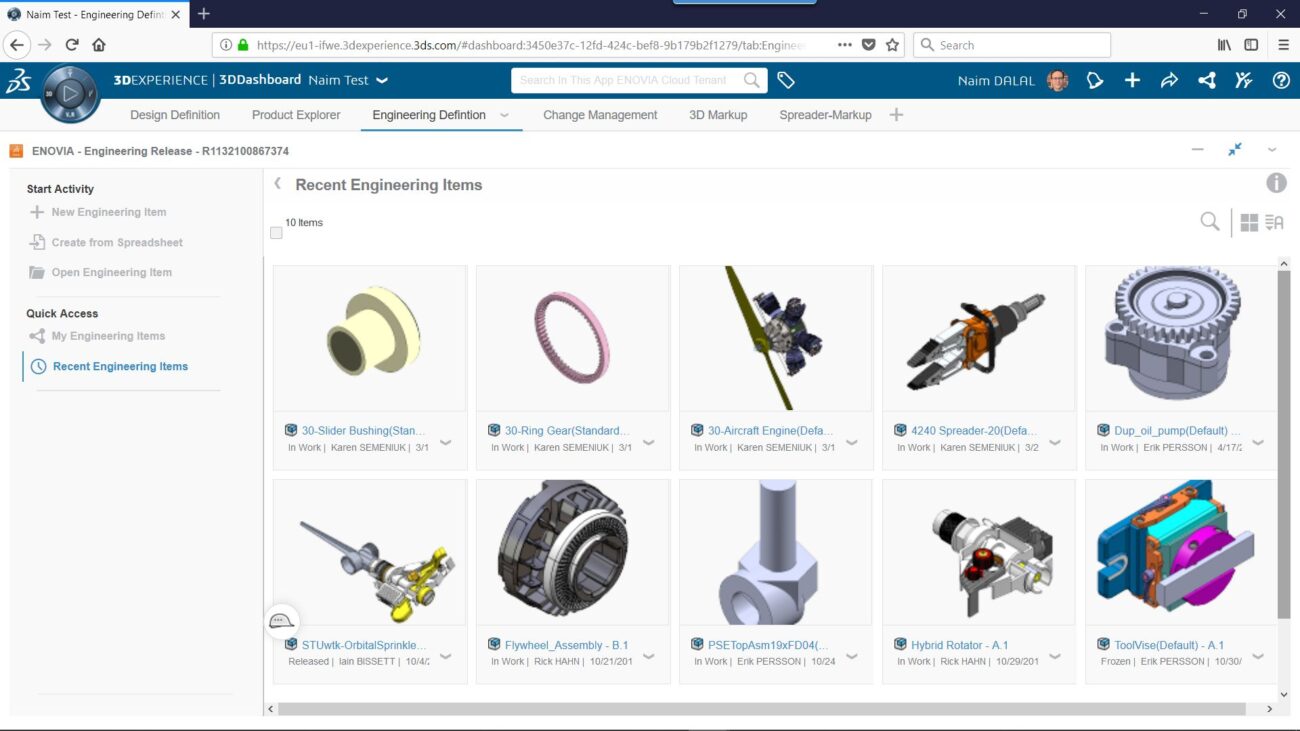

Leverage collaboration and simulation on 3DEXPERIENCE On-Cloud

Streamline the digital prototyping workflow by connecting CAD, VR experiences, simulation, offline programming, and plant optimization in one powerful collaboration engine with 3DEXPERIENCE Industry Process Experiences.

Industrial Equipment Clients

Delivering Digital Continuity Across the Virtual and Real Worlds of Manufacturing

-

Posted by

VIAS3D

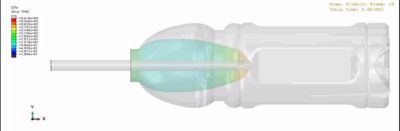

Application of Finite Element Analysis for Industrial Equipment

-

Posted by

VIAS3D

Simulating Blow Molding Process through Finite Element Analysis using Abaqus

-

Posted by

VIAS3D

Product and Process Optimization of Pressure Ventilation Fan using SIMULIA Abaqus

-

Posted by

VIAS3D